Understanding the Three-Step Method

Ensuring product safety is one of the most critical responsibilities for manufacturers. However, every product inherently carries some level of risk. The key question is how to effectively reduce these risks. The “Three-Step Method” (also known as the 3-Step Method) has been established as a systematic approach to address this challenge.

Ensuring product safety is one of the most critical responsibilities for manufacturers. However, every product inherently carries some level of risk. …

Fundamental Concepts of the Three-Step Method

The Three-Step Method is a technique that clearly defines the priorities when implementing risk reduction measures. This method is explicitly described in ISO 12100:2010 (Safety of machinery – General principles for design – Risk assessment and risk reduction), which serves as the internationally recognized fundamental principle of safe design. The current version, ISO 12100:2010, is undergoing revision, with ISO/DIS 12100 published as a draft in December 2024 and expected to be officially released in 2026. The Three-Step Method principles remain consistent in the revised version.

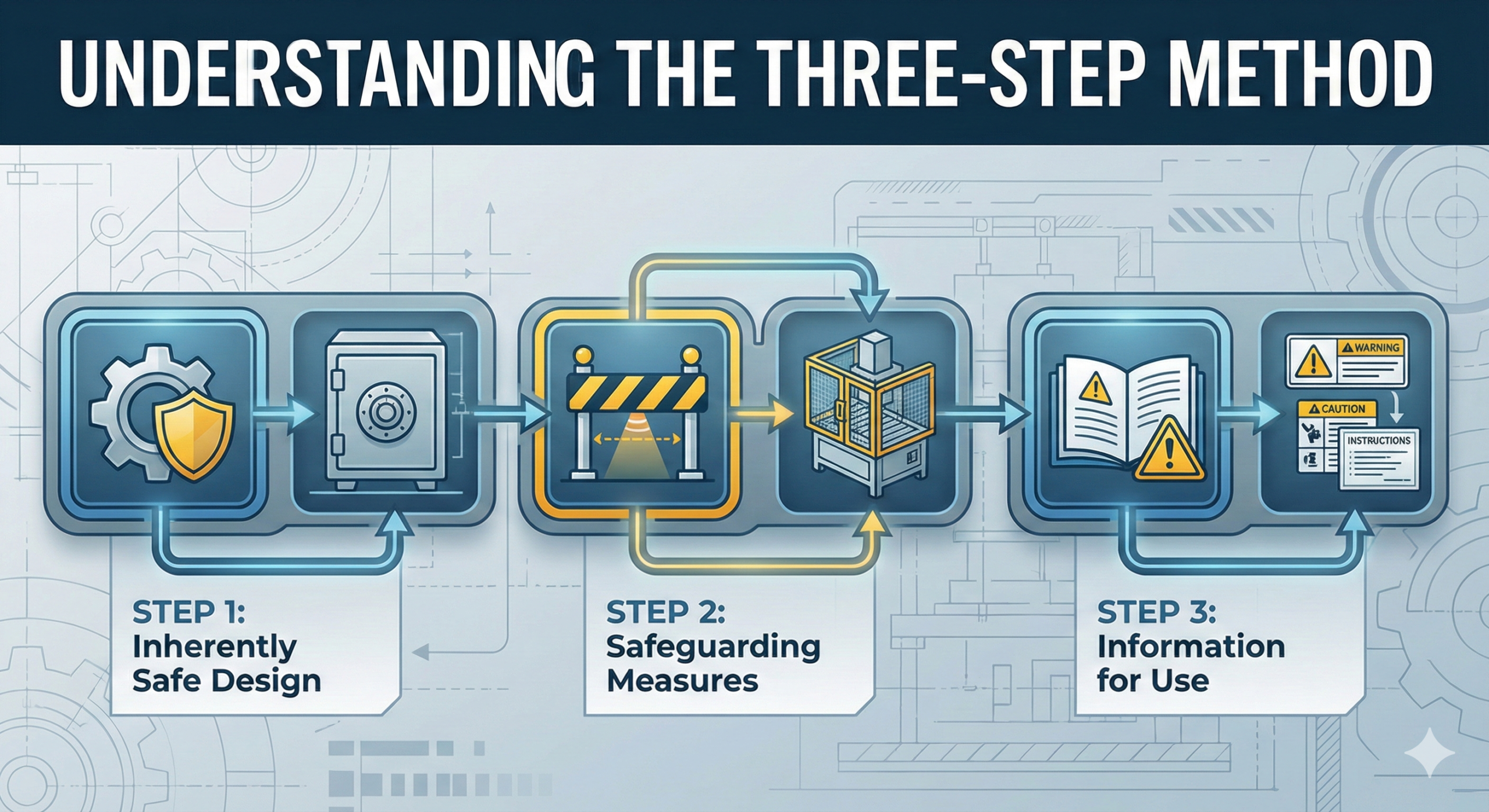

The core of this method lies in classifying risk reduction measures into the following three steps and examining and implementing them strictly in numerical order:

- Inherently safe design measures (elimination or reduction of risks through design)

- Safeguarding and complementary protective measures (installation of guards and protective devices)

- Information for use (warning displays and instruction manuals)

It is crucial to follow this sequence. This is because later steps increasingly depend on human attention and behavior, resulting in decreased reliability.

Detailed Explanation of Each Step

Step 1: Inherently Safe Design Measures

The first step involves eliminating or reducing risks themselves during the design phase. This represents the most fundamental and effective countermeasure.

Practical Examples from Daily Life

Consumer products:

- Electric kettles: Positioning the steam outlet in locations difficult for hands to reach

- Stationery: Rounding scissors tips to reduce the risk of accidental puncture

- Toys: Designing without small parts to eliminate choking hazards

- Automobiles: Adopting body structures that absorb impact during collisions

Examples in Industrial Machinery:

- Rounding sharp corners

- Replacing hazardous chemicals with harmless alternatives

- Reducing the speed of moving parts to safe levels

- Covering high-temperature parts with insulation to lower surface temperatures

The greatest advantage of this step is that it can reliably reduce risks even with the premise that “humans make mistakes.” Since design changes eliminate the hazard source itself, accidents will not occur regardless of how careless users may be.

Step 2: Safeguarding and Complementary Protective Measures

When design measures alone cannot sufficiently reduce risks, the next consideration should be the installation of protective devices. This is a countermeasure that also considers the possibility that “machines can fail.”

Everyday Examples:

- Microwave ovens: Interlock function that prevents operation when the door is open

- Washing machines: Mechanism that automatically stops when the lid is opened during rotation

- Elevators: Safety devices that prevent movement unless doors are completely closed

Examples at Industrial Sites:

- Acrylic panels or covers enclosing moving parts of machinery

- Two-hand simultaneous operation switches (both hands are occupied, preventing hands from entering dangerous zones)

- Photoelectric safety devices (light curtains)

- Installation of emergency stop buttons

These protective measures prevent accidents by physically separating hazards from people or by immediately stopping machinery when dangerous situations occur. While not as reliable as Step 1, they demonstrate high effectiveness when properly designed and installed.

Step 3: Information for Use

For residual risks that remain even after implementing the aforementioned two steps, users are provided with information to address them. This is the third step and represents the last resort.

Types and Examples of Information Provision

1. Displays on the Product Itself

- Warning labels (caution: high temperature, electrical shock hazard, etc.)

- Simple operation method displays

- Alarm sounds and warning lights

2. Written Information

- Precautions in instruction manuals

- Package inserts (for pharmaceuticals and medical devices)

- Quick guides

3. Education and Training

- User training

- Safety workshops

- Online educational materials

However, this step has significant limitations. No matter how clear the warnings, there is always the possibility they may be overlooked, ignored, or misunderstood. Therefore, relying solely on this step must be avoided.

Why This Sequence Matters

The true value of the Three-Step Method lies in this sequence. Let us examine in more detail why following this order is important.

1. Differences in Effectiveness Reliability

There are clear differences in the reliability of effectiveness for each step:

- Step 1 (Design): Nearly 100% reliability. Always functions regardless of user behavior

- Step 2 (Protection): High reliability. However, risks exist for protective device failure or disabling

- Step 3 (Information): Uncertain. Completely dependent on human comprehension, attention, and compliance

For example, consider the hazard of rotating blades. Covering blades with guards (Step 2) is more reliable than not using blades at all in the design (Step 1). A warning display stating “Beware of blades” (Step 3) alone is insufficient to prevent accidents.

2. Cost and Liability Perspectives

Cost Advantages:

- Design-stage changes are significantly less expensive than post-manufacturing modifications

- Prevents costs associated with accident-related damages and loss of trust

- Reduces recall cost risks

Legal Liability Perspective:

Manufacturing liability laws in many countries assign responsibility in the following order:

- Design defects (most severe liability)

- Manufacturing defects

- Instruction and warning defects (relatively lighter liability)

In other words, if risks that could have been addressed through design are only managed with warning displays, the manufacturer’s liability becomes heavier.

3. Human Factors Basis

When premised on the realities that “humans make mistakes” and “machines fail”:

- Human attention capacity is limited (particularly attention decreases during repetitive tasks)

- Under time pressure, safety procedures tend to be skipped

- With accumulated experience, complacency due to familiarity tends to develop

Considering these human characteristics, it is rational to implement measures that do not depend on human behavior (Step 1) first in sequence.

Challenges and Responses in Practice

While theoretically clear, the Three-Step Method faces various challenges in practice.

Technical and Functional Constraints

Complete elimination of all risks through design is often impossible.

Example 1: Kitchen Knives

- Risk: Danger of cuts

- Ideal countermeasure: Eliminate the blade → However, this results in loss of cutting function

- Realistic countermeasure: Easy-grip handle design (Step 1) + protective case (Step 2) + usage instructions (Step 3)

Example 2: Automobiles

- Risk: Collision accidents

- Ideal countermeasure: Limit speed to walking pace → However, loses value as a means of transportation

- Realistic countermeasure: Collision-safe body (Step 1) + airbags and ABS (Step 2) + safe driving awareness campaigns (Step 3)

Pursuing Reasonable Balance

ISO 12100 presents the concept of “ALARP (As Low As Reasonably Practicable).” This means achieving maximum risk reduction:

- Within technically feasible ranges

- Within economically reasonable ranges

- Within socially acceptable ranges

The ALARP principle, developed primarily in UK health and safety law, has been adopted in various industries worldwide. It recognizes that risks must be reduced to levels where the cost of further reduction would be grossly disproportionate to the safety benefit gained.

| Risk Level | Action Required |

| Intolerable Risk (Above Upper Tolerability Limit) | Must be reduced regardless of cost |

| ALARP Region (Between Upper and Lower Tolerability Limits) | Must be reduced unless costs are grossly disproportionate to benefits |

| Broadly Acceptable Risk (Below Lower Tolerability Limit) | Maintain existing controls to prevent degradation |

Integration with Risk Assessment

Effective application of the Three-Step Method requires prior risk assessment:

- Hazard identification: What dangers exist?

- Risk estimation: Degree of harm and probability of occurrence

- Risk evaluation: Judgment of acceptability

- Risk reduction: Application of the Three-Step Method

- Re-evaluation: Confirmation of risk levels after countermeasures

By repeating this cycle, systematic risk reduction becomes possible.

Industry-Specific Application Examples

Medical Device Industry

- Step 1: Development of needle-free injectors (fundamental solution to needlestick accidents)

- Step 2: Safety-featured injection needles (automatically covered after use)

- Step 3: Explanation of disposal methods in instruction manuals

Construction Industry

- Step 1: Changing high-altitude work to ground-level work (adoption of prefabrication methods)

- Step 2: Installation of safety nets and handrails

- Step 3: Instructions for wearing safety harnesses, hazard prediction (KY) activities

Food Manufacturing Industry

- Step 1: Product design not using allergens

- Step 2: Physical separation of production lines

- Step 3: Allergen labeling and cautionary notices

Alignment with Current Regulatory Developments

EU Machinery Regulation (EU) 2023/1230

The new EU Machinery Regulation (EU) 2023/1230, adopted on June 14, 2023, replaces the previous Machinery Directive 2006/42/EC and will become fully applicable from January 20, 2027. This regulation incorporates significant updates relevant to the Three-Step Method:

Key Updates:

- Enhanced requirements for cybersecurity and protection against data corruption in safety-critical systems

- Specific provisions for machinery incorporating artificial intelligence (AI) and machine learning

- Updated essential health and safety requirements (EHSRs) in Annex III that align with modern risk assessment methodologies

- Digital documentation options for instructions for use and declarations of conformity

The regulation maintains the fundamental principles of the Three-Step Method while addressing emerging risks from digitalization, connectivity, and autonomous systems. Manufacturers must now consider cybersecurity threats as safety hazards requiring systematic risk reduction through inherently safe design, safeguarding measures, and appropriate user information.

ISO 12100 Revision

As of early 2025, ISO 12100 is undergoing revision with ISO/DIS 12100 published for comment in December 2024. The revision includes:

- Updated definitions and terminology

- Alignment with the EU Machinery Regulation (EU) 2023/1230

- New subsection on cybersecurity and protection against corruption (6.3.5.17)

- Enhanced guidance on addressing risks from AI and autonomous systems

- References to relevant standards such as ISO/IEC 24392 for cybersecurity

The revised standard is expected to be published in 2026, maintaining the core Three-Step Method principles while providing updated guidance for contemporary technologies.

Summary

The Three-Step Method is a powerful tool for systematically improving product safety. By adhering to the priority sequence of inherently safe design, protective measures, and information for use, more reliable and effective risk reduction becomes possible.

Key Points to Remember:

- Always follow the sequence: Consider in the order of Step 1 → 2 → 3

- Prioritize measures not dependent on people: Premise that “humans make mistakes”

- Maximum effort within reasonable ranges: Do your best within technical and economic constraints

- Clarify residual risks: Always communicate risks that remain after countermeasures to users

- Consider emerging risks: Address cybersecurity, AI, and digital connectivity hazards through the Three-Step hierarchy

By properly applying this method, manufacturers can improve product safety, protect users, and simultaneously reduce their own legal risks. Creating safe products is not merely regulatory compliance but represents corporate social responsibility and the foundation of sustainable business.

When all stakeholders involved in product development understand and practice the principles of this Three-Step Method, it leads to the realization of a safer society. As technology evolves and new hazards emerge from digitalization and artificial intelligence, the systematic approach provided by the Three-Step Method becomes increasingly essential for managing complex, interconnected risks in modern machinery and products.

Related Articles

- Understanding Amendment Methods in Regulatory Requirements: The Case of Partial Amendments

- Understanding the 3 Step Method

- Understanding CFR: The Foundation of U.S. Regulatory Framework

- Understanding the “Typewriter Excuse” in FDA 21 CFR Part 11 Compliance

- Why Printouts Cannot Be Trusted: Understanding the Vulnerability of Paper-Based Document Management

- Understanding the True Purpose of Performance Qualification (PQ) in Computerized System Validation

Comment