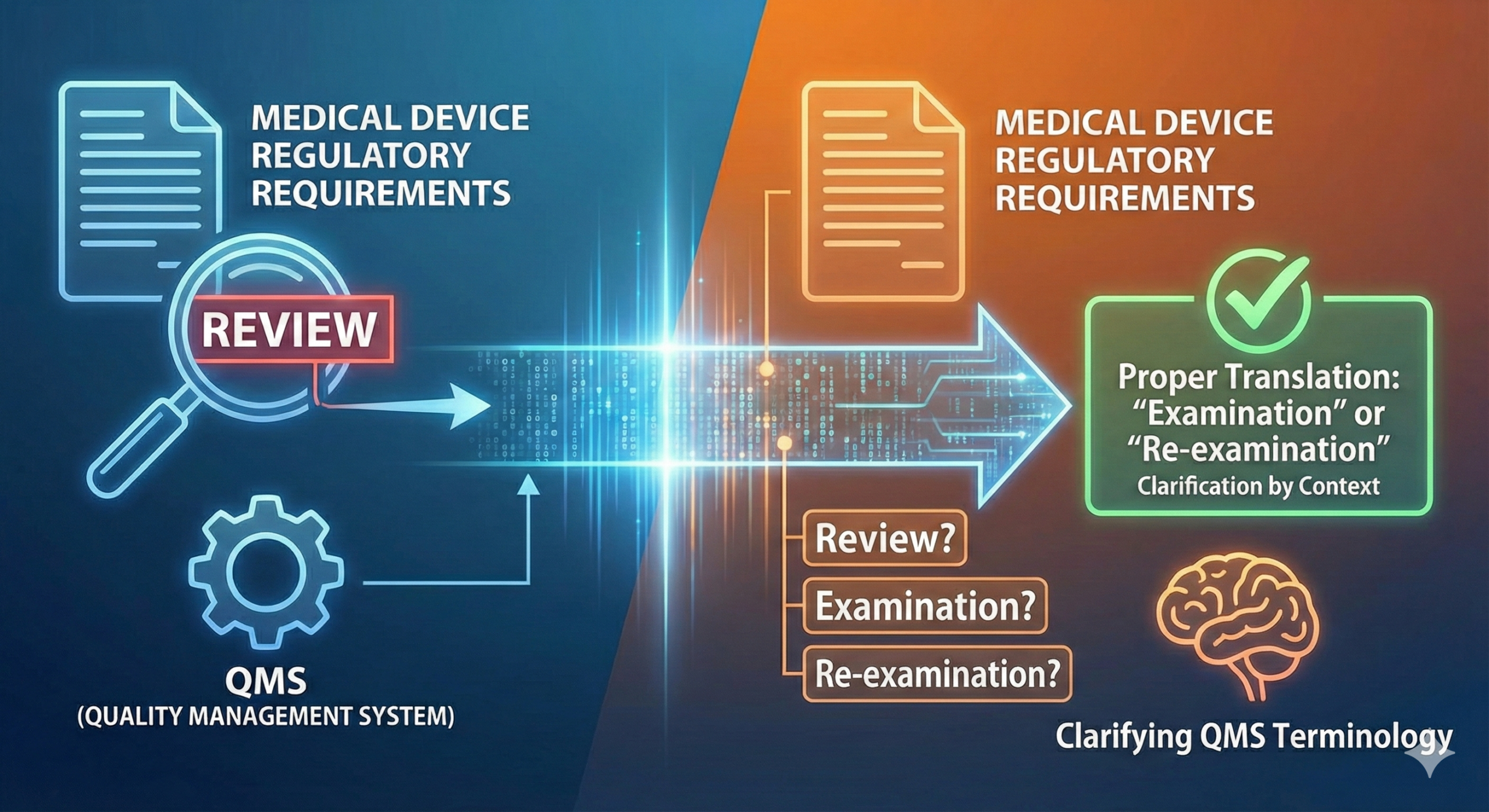

Proper Japanese Translation of “Review” in Medical Device Regulatory Requirements: Clarifying Terminology in Quality Management Systems

Introduction

The term “review” appears repeatedly throughout ISO 13485 and FDA QSR (Quality System Regulation) documents. Specific terms such as “design review,” “management review,” and “periodic review” are established as regulatory requirements. However, the proper Japanese translation of this English term “review” significantly impacts understanding and implementation of quality management systems. In fact, “review” must be translated differently depending on context—a distinction that extends far beyond simple terminology selection, as it fundamentally affects the importance and scope of responsibility in actual business processes. This article explains the appropriate Japanese translations of “review” in medical device regulations and clarifies the regulatory meaning embedded within each translated term.

The term “review” appears repeatedly throughout ISO 13485 and FDA QSR (Quality System Regulation) documents. Specific terms such as “design review,” “…

Design Review Should Be Translated as “審査” (Shinsa—Formal Examination)

Rationale for Terminology Selection

Design Review, as defined in ISO 13485 Section 8.3 and FDA QSR, is most appropriately translated into Japanese as “Sekkei Shinsa” (設計審査, literally “Design Examination”). This translation choice transcends mere linguistic substitution; it reflects the essential function of design review in regulatory contexts.

Design examination is a process that critically validates and renders judgment on whether a design under development conforms to regulatory requirements, safety standards, and the organization’s quality policy. In other words, design is not merely “confirmed” or “checked”—rather, its appropriateness, consistency, coherence, and safety are subject to formal examination.

Real-World Application in Medical Device Development

Consider medical electrical equipment (medical ME devices) as a practical example. In design examination, each technical discipline—mechanical design, electrical/electronic design, and software design—is evaluated from a comprehensive perspective. As teams in each discipline independently advance their respective designs, it becomes essential to verify whether the combination of these designs collectively ensures the device’s performance, safety, and alignment with its intended use. Design examination aims to detect integrated issues that individual departments might overlook: inconsistencies at the interface between mechanical and software design domains, unresolved interference between electrical and mechanical systems, and the validity of redundancy configurations in safety-critical functions. These integrated considerations cannot be achieved through superficial confirmation alone.

Pass/Fail Determination and Iterative Process

Because design examination involves formal judgment, it necessarily includes explicit pass/fail decisions. When design fails to meet examination criteria, it must be returned to the design team with documented reasons, and the cycle of revision and re-examination must continue until design achieves conformance. This iterative process itself is the mechanism ensuring design quality—a level of rigor that simple confirmation cannot achieve. Both FDA QSR and ISO 13485 mandate detailed documentation of design review, establishment of review timelines at appropriate development stages, and clear records precisely because they emphasize the importance of this pass/fail determination and iterative process.

Terminology in Japan’s Medical Device QMS Regulation

Notably, Japan’s Medical Device QMS Ordinance (Ministry of Health, Labour and Welfare Ordinance No. 169) translates the design review requirement as “Shōsa” (照査, literally “Comparative Examination”). The term “Shōsa” carries semantic proximity to “Shinsa” (審査), both implying evaluation against established standards or criteria. Within this ordinance, “Shōsa” is not mere confirmation but a process of verifying that design meets QMS Ordinance requirements, which aligns with the original intent of ISO 13485 and FDA QSR. However, when creating domestic guidance documents or SOPs, using the term “Sekkei Shinsa” (Design Examination) can more effectively prevent misunderstanding that design review is simply “design confirmation” and enables clearer communication with stakeholders.

Management Review Should Be Translated as “Minaooshi” (見直し—Periodic Review/Revision)

Rationale for Terminology Selection

Conversely, “Management Review” as defined in regulatory standards is most appropriately translated as “Minaooshi” (見直し, literally “Periodic Revision”) in Japanese. This refers to a process in which senior management periodically examines the entire QMS, quality policy, quality objectives, resource allocation, and QMS effectiveness, and implements corrections or improvements as necessary.

Whereas design examination emphasizes “rendering judgment,” management review characterizes a strategic activity of “periodic inspection and directional adjustment.” This activity integrates multiple evaluative factors: achievement of quality objectives, analysis of manufacturing and sales data, customer feedback, changes in the regulatory environment, and business constraints. Through this comprehensive evaluation, management assesses overall QMS effectiveness and makes strategic decisions regarding next-period quality objectives and resource allocation.

Function and Responsibility in Management Review

Management review is emphatically not a forum where management passively listens to reported circumstances. Rather, it is a deliberative process where senior management actively examines quality information and renders management decisions regarding QMS revision, additional resource allocation, and modification of quality policy. ISO 13485 Section 5.6 specifies in detail the input information required for management review—including internal audit results, product conformance status, corrective and preventive action status, change management status, and regulatory requirement updates. The standard requires that organizational improvement directions be determined based on this information.

Similarly, FDA QSR and 21 CFR Part 820.22(b) clearly define management responsibility to conduct periodic review, confirm QMS effectiveness, and direct necessary improvement measures. Because this responsibility is clearly assigned, the term “Minaooshi” (Periodic Review) is precisely appropriate. Through periodic review, organizations confirm whether the QMS remains suitable for their current circumstances and provide directional guidance for continuous improvement.

Relationship to Other Review Activities

Medical device QMS encompasses multiple review activities beyond management review: Product Review, Risk Management Review, and in software development, Peer Review. Among these, risk management review and peer review, which serve technical verification purposes, may warrant translations such as “Shinsa” (審査, Examination) or “Kensatsu” (検査, Inspection). Conversely, management review, which serves strategic organizational direction-setting, is best expressed through the term “Minaooshi” (見直し, Periodic Review), which most accurately characterizes its nature.

Impact of Consistent Terminology

Critical Importance in QMS Documentation

Quality assurance departments at medical device manufacturers create internal SOPs (Standard Operating Procedures) and quality manuals based on ISO 13485 and FDA QSR. The translation of “review” in these internal documents directly influences employee understanding and execution. Should a company’s SOP translate “design review” as “design confirmation,” engineering teams may fail to recognize the critical nature of formal examination and might conduct only superficial checks. Similarly, should “management review” be translated as “administrative meeting,” senior management responsibility for proactive improvement planning could become ambiguous.

Regulatory Authority Interactions

Furthermore, post-market regulatory interactions with authorities (PMDA, FDA, European Medicines Agency, etc.) scrutinize terminology precision. Should an inspection reveal that a company’s SOPs translate “review” inappropriately, regulators may conclude the company lacks proper understanding of ISO 13485 or FDA QSR requirements. Even if the interaction does not result in formal findings or warning letters, citation as an observation (Observation) can create unnecessary subsequent revision burden and delays.

Conclusion: Recommended Terminology Standardization

To organizations developing and operating QMSs compliant with ISO 13485 or FDA QSR, we emphasize the following: Should your organization’s QMS documents (SOPs, quality manuals, and other documentation) currently translate “review” simply as “confirmation,” we strongly recommend immediate revision. Instead, employ the following translations according to context:

- Design Review → “Sekkei Shinsa” (設計審査, Design Examination) or “Sekkei Shōsa” (設計照査, Design Verification)

- Management Review → “Minaooshi” (見直し, Periodic Review) or “Keiei Minaooshi” (経営見直し, Management Revision)

This terminology change transcends mere wordsmithing; it constitutes a foundational step in ensuring comprehensive understanding and implementation of quality management principles. By employing precise terminology, organizations enhance employee training effectiveness, ensure more reliable regulatory compliance, and ultimately advance the quality and safety of medical devices offered to patients and healthcare systems.

Related Articles

- Complaint Management in Medical Device Quality Systems

- Quality Management Systems in Medical Device Regulation

- Data Analysis in Medical Device and Pharmaceutical Quality Management Systems

- Understanding Quality Systems in Pharmaceutical and Medical Device Industries

- Regulatory Requirements for Medical Device Software Development

- Quality Systems in Pharmaceutical Manufacturing: A Critical Analysis of Regulatory Requirements and Organizational Structures

Comment