Requirements Management Challenges in System Development

One of the most fundamental yet challenging tasks in system development projects is to “implement what users require—no more, no less.” While this may seem like a straightforward objective, actual projects frequently encounter the following problems.

First, some user requirements may be overlooked during the design phase and not implemented. This is called requirements gap or omission, meaning the system is completed without essential functionality it should provide. Conversely, functions that users did not request may sometimes be implemented. This not only wastes development resources but also unnecessarily increases system complexity, reducing maintainability and reliability.

The traceability matrix is a management methodology developed to prevent such problems.

Basic Concept of Traceability Matrix

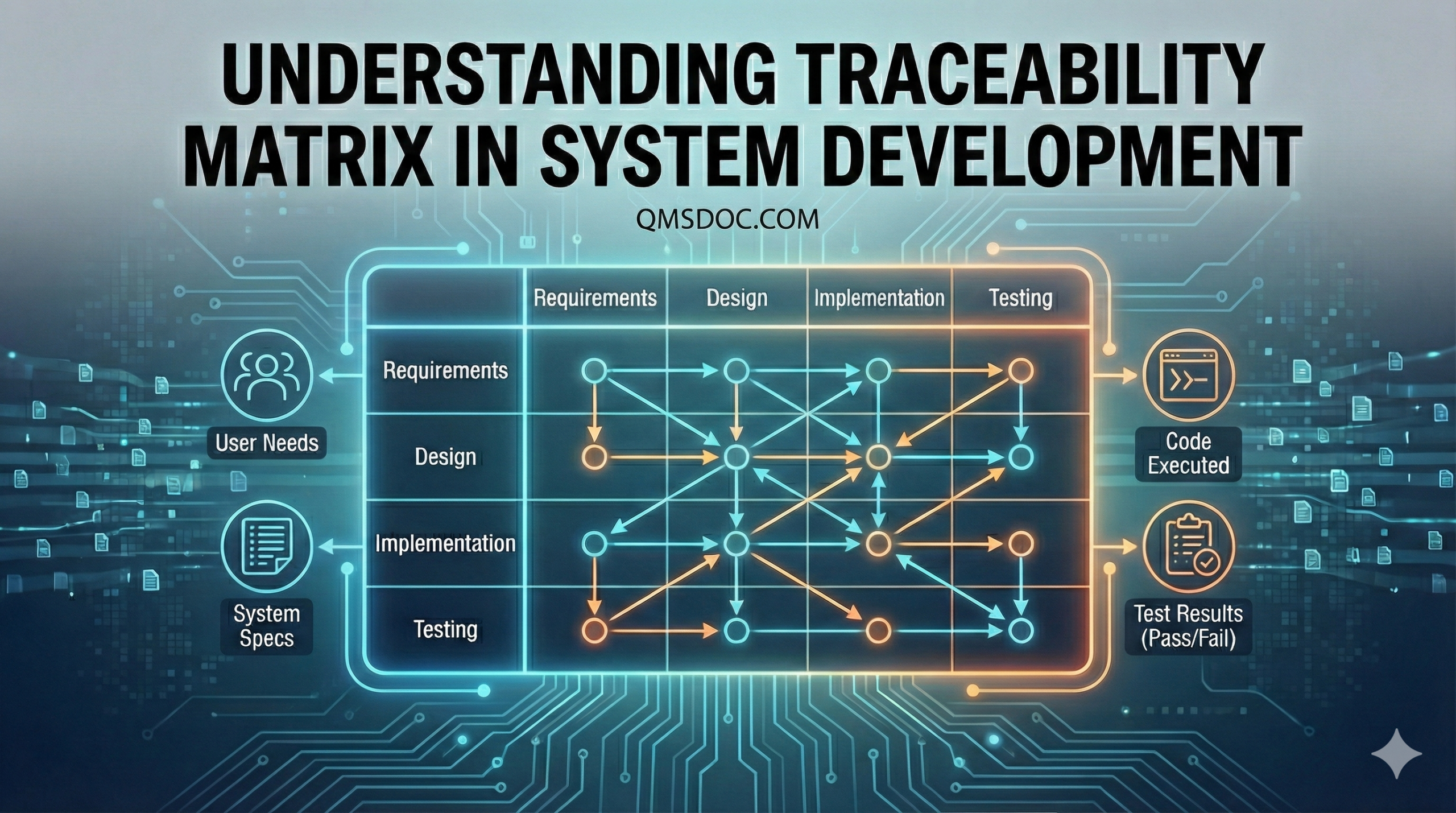

A traceability matrix is a tabular tool that visualizes the relationships between various deliverables in system development. In its most basic form, user requirements are placed on the vertical axis and functional specifications on the horizontal axis, with their corresponding relationships indicated on the matrix grid.

For example, if a user requirement “UR-001: The system shall provide user authentication functionality” corresponds to functional specifications “FS-001: Login screen provision,” “FS-002: Password verification function,” and “FS-003: Session management function,” marking the intersection points on the matrix clearly demonstrates the relationship between requirements and specifications.

Bidirectional Traceability

An important characteristic of the traceability matrix is that it provides bidirectional traceability.

Forward traceability starts from user requirements and tracks how they are developed into functional specifications, design specifications, and test cases. This confirms that all user requirements are properly implemented.

Backward traceability works in reverse, tracing back from implemented functions or created test cases to identify which user requirements they are based on. This enables the discovery and elimination of unnecessary function implementations.

Why Traceability Matrix is Necessary

Ensuring Requirements Completeness

As projects become larger and more complex, managing all user requirements mentally becomes impossible. When dealing with dozens or hundreds of requirement items, a systematic management methodology is essential to verify that each is properly designed and implemented.

Using a traceability matrix allows visual confirmation that at least one or more functional specifications correspond to each user requirement. If no corresponding specification exists for a requirement, that row remains blank, making the requirement gap immediately apparent.

Eliminating Unnecessary Functions

Equally important is preventing the implementation of functions that users have not requested. Developers sometimes add unrequested features out of good intentions, thinking “this feature would be convenient.” However, such “kindnesses” can cause the following problems:

- Increased development time and costs

- Reduced maintainability due to system complexity

- Occurrence of unexpected bugs and security vulnerabilities

- Complicated user interfaces

The traceability matrix confirms that all functional specifications are associated with at least one user requirement. Functional specifications without such associations are identified as unnecessary functions and become candidates for deletion.

Eliminating Excess and Insufficiency in Validation

Importance of Validation in Regulated Industries

In regulated industries such as pharmaceutical manufacturing and medical device development, system validation is a legal requirement. Validation is an activity that ensures through documented evidence that a system is appropriate for its intended use.

Problems with Excessive Validation

When validation activities become excessive, the following problems occur:

- Waste of cost and time due to unnecessary testing

- Increased burden of document creation

- Insufficient focus on truly important verification activities

- Project delays

Risks of Insufficient Validation

Conversely, when validation activities are insufficient, more serious problems occur:

- Verification gaps for important functions

- Non-compliance with regulatory requirements

- Overlooking quality issues

- In the worst case, potential impact on patient safety

The traceability matrix serves as an important tool to prevent such excess and insufficiency. By visualizing the entire flow from requirements through design, implementation, and testing, necessary and sufficient validation activities can be planned and executed.

Regulatory Requirements and Standards

IEC 62304 Requirements

IEC 62304 is an internationally recognized standard for medical device software lifecycle processes, endorsed by regulatory authorities worldwide including the FDA, Health Canada, and the European Commission. The standard explicitly requires traceability throughout the software development lifecycle.

According to IEC 62304, manufacturers must establish and maintain traceability between:

- System requirements and software requirements

- Software requirements and software architecture

- Software architecture and software detailed design

- Software requirements and software system tests

- Risk control measures and their verification

The standard introduces a risk-based classification system (Class A, B, and C) based on the potential harm to patients. Class C software, where failure could result in death or serious injury, requires the most comprehensive traceability documentation.

IEC 62304 Software Safety Classification

| Safety Class | Definition | Traceability Requirements |

|---|---|---|

| Class A | No injury or damage to health is possible | Basic traceability documentation |

| Class B | Non-serious injury is possible | Comprehensive traceability including detailed design |

| Class C | Death or serious injury is possible | Full traceability including all verification and risk control measures |

FDA Requirements

The U.S. Food and Drug Administration (FDA) requires traceability as part of the Quality System Regulation (QSR), outlined in 21 CFR Part 820. Specifically, 21 CFR Part 820.30 mandates clear links between design inputs, design outputs, and verification activities.

The FDA recently transitioned from the QSR to the Quality Management System Regulation (QMSR), which adopts ISO 13485:2016 as its foundation. This alignment with international standards strengthens traceability requirements, particularly for implantable and life-supporting/life-sustaining devices.

FDA reviewers expect to see a comprehensive traceability matrix during premarket submissions (510(k) or PMA). A well-structured traceability matrix is often the primary evidence demonstrating that design controls have been properly implemented and that all requirements have been adequately addressed.

ISO 13485:2016 Requirements

ISO 13485:2016 is the internationally recognized standard for medical device quality management systems. The standard requires organizations to document procedures for traceability, defining the extent of traceability in accordance with applicable regulatory requirements.

Key traceability requirements under ISO 13485:2016 include:

-

Identification throughout lifecycle: All products, including components and raw materials, must be identified throughout their lifecycle using unique identifiers such as serial numbers, batch numbers, or lot codes.

-

Traceability records: Organizations must maintain records tracking the history of each device, including materials, components, manufacturing processes, and design changes.

-

Special requirements for implantable devices: ISO 13485:2016 Section 7.5.9.2 mandates additional traceability requirements for implantable medical devices, including records of components, materials, and work environment conditions that could affect device safety and performance.

-

Distributor traceability: Manufacturers must require distributors to maintain distribution records that enable traceability and make these records available for inspection.

EU Medical Device Regulation (MDR)

The European Union Medical Device Regulation (EU MDR), which came into force in May 2021, prioritizes closed-loop quality system traceability. The MDR requires:

- Total lifecycle traceability between all stages of medical device development, manufacturing, distribution, and post-market activities

- Unique Device Identification (UDI) system for tracking devices throughout their lifecycle

- All third-party suppliers and manufacturers involved in any stage of a medical device’s lifecycle must undergo QMS audits to demonstrate compliance with traceability requirements

- Economic operators (manufacturers, authorized representatives, importers, and distributors) must cooperate in maintaining traceability

Practical Construction of Traceability Matrix

Staged Expansion

In actual projects, the traceability matrix is expanded in stages. It begins with the correspondence between user requirements and functional specifications, and the following elements are added as the project progresses:

- User Requirement Specifications (URS) → Functional Specifications (FS)

- Functional Specifications (FS) → Design Specifications (DS)

- Design Specifications (DS) → Source Code/Modules

- Each Specification → Test Cases

- Test Cases → Test Results

- Requirements → Risk Control Measures

- Risk Control Measures → Verification Evidence

Matrix Management and Updates

The traceability matrix is not a one-time deliverable—it requires continuous management and updates throughout the project. Updates are particularly important at the following times:

- When requirements are added, changed, or deleted

- During design reviews

- When establishing or modifying test plans

- Upon discovery of problems or defects

- When risk assessments are updated

Tool Utilization

For small-scale projects, spreadsheet software can be used to manage the traceability matrix. However, as projects scale up, the use of dedicated requirements management tools or ALM (Application Lifecycle Management) tools is recommended. Modern tools commonly used in the medical device industry include:

- JAMA Connect: Provides comprehensive requirements management and traceability

- IBM DOORS: Long-established tool with robust traceability capabilities

- Polarion: Collaborative platform for requirements and lifecycle management

- Helix ALM: Supports FMEA, requirements traceability, and testing documentation

- Ketryx: Integrates with development tools like Jira and Git to automate traceability documentation

These tools provide automatic consistency checking and change management functions, supporting the maintenance of traceability. They also enable integration with development platforms, reducing manual documentation burden while ensuring compliance.

Comparison of Traceability Management Approaches

| Approach | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Spreadsheets (Excel) | Low cost, familiar interface, easy to start | Manual updates error-prone, version control difficult, doesn’t scale well | Small projects, limited requirements (< 50 items) |

| Requirements Management Tools | Automated traceability, version control, change impact analysis | Higher cost, learning curve, requires validation | Medium to large projects, regulated industries |

| Integrated ALM Platforms | End-to-end lifecycle management, tool integration, audit readiness | Highest cost, complex implementation | Large organizations, complex products, multiple teams |

Consistency Verification as a Quality Assurance Cornerstone

Consistency verification using the traceability matrix is not merely a document management methodology. It forms the foundation for activities that ensure system quality.

Reviews and Inspections

The traceability matrix serves as an important input for reviews and inspections at each development phase. For example, during design reviews, the matrix is used to confirm that all user requirements are reflected in the design specifications. Similarly, during test plan reviews, it is verified that test cases have been created for all functional specifications.

Change Impact Analysis

When requirement changes occur during system development, the traceability matrix becomes an important tool for identifying the scope of change impact. It enables rapid understanding of which functional specifications, design specifications, and test cases are affected by changes to a particular requirement. This allows proper assessment of risks associated with changes and planning of necessary responses.

Example of Change Impact Analysis

Consider a scenario where a user requirement for authentication is modified to add biometric authentication support. Using the traceability matrix, the development team can quickly identify:

- Which functional specifications must be updated (login mechanisms, security protocols)

- Which design components are affected (authentication module, database schema)

- Which test cases need revision (authentication tests, security tests)

- Which risk assessments require updating (security risks, usability risks)

- Which documentation needs modification (user manuals, validation reports)

This systematic approach ensures that no downstream impacts are overlooked when requirements change, reducing the risk of introducing defects or compliance gaps.

Regulatory Compliance and Audit Support

In regulated industries, ensuring traceability is often a legal requirement. For example, in medical device software development, standards such as IEC 62304, ISO 13485, and FDA regulations require the establishment of traceability. The traceability matrix serves as important evidence documentation demonstrating conformity with these regulatory requirements.

During audits and regulatory inspections, auditors expect to see clear evidence that:

- All requirements have been traced to design outputs

- All design outputs have been verified

- All risks have been controlled and verified

- Changes have been properly managed and their impacts assessed

A well-maintained traceability matrix significantly streamlines the audit process by providing immediate access to this evidence. It also demonstrates systematic quality management practices, which can positively influence regulatory reviewers’ assessment of the organization’s overall quality culture.

Best Practices for Traceability Matrix Implementation

Establishing Clear Traceability Policies

Organizations should establish clear policies defining:

- Traceability scope: Which artifacts require traceability and to what level

- Identification scheme: Consistent naming and numbering conventions for requirements, specifications, and test cases

- Update frequency: When and how often traceability information must be updated

- Responsibility: Who is responsible for creating and maintaining traceability data

- Review requirements: How often traceability completeness is verified

Integrating with Development Workflows

To avoid traceability becoming a burden, it should be integrated naturally into existing development workflows:

- Requirement creation: When new requirements are documented, establish traceability links immediately

- Design activities: Link design specifications to requirements as they are created

- Development: Associate code commits or modules with design specifications

- Testing: Link test cases to requirements and specifications when tests are written

- Reviews: Verify traceability completeness during phase reviews

Leveraging Automation

Modern tools can significantly reduce the manual effort required to maintain traceability:

- Automated link creation: Tools can automatically create traceability links based on references in documents

- Impact analysis: Automated identification of affected items when changes occur

- Coverage reporting: Automatic generation of coverage reports showing which requirements lack implementation or testing

- Compliance reporting: Automated generation of traceability reports for regulatory submissions

Training and Culture

Successful traceability implementation requires appropriate training and organizational culture:

- Developer training: Ensure all team members understand the importance of traceability and how to maintain it

- Tool training: Provide comprehensive training on traceability tools and systems

- Quality culture: Foster a culture where traceability is viewed as enabling quality rather than bureaucratic overhead

- Continuous improvement: Regularly review and improve traceability processes based on lessons learned

Challenges and Solutions in Agile Development

Adapting Traceability to Agile

Traditional traceability approaches were developed for waterfall methodologies, but they can be successfully adapted to Agile development. IEC 62304 explicitly acknowledges that Agile methods can be used, noting that “planning is an iterative activity that should be repeatedly reviewed and updated as development progresses.”

Key considerations for Agile traceability:

- User stories as requirements: User stories can serve as requirements items in the traceability matrix

- Sprint-level traceability: Maintain traceability at the sprint level while aggregating to release level

- Continuous updates: Update traceability information as part of sprint activities, not as a separate phase

- Definition of done: Include traceability updates in the definition of done for user stories

Hybrid Approaches

Many regulated organizations adopt hybrid development models that combine upfront design control with Agile execution:

- High-level requirements and risk assessments are defined upfront

- Implementation and testing follow iterative sprints

- Traceability is maintained by linking sprint outputs back to formal requirements

- Regular checkpoints verify traceability completeness

This approach maintains regulatory compliance while allowing development teams to benefit from Agile’s flexibility and iterative approach.

Conclusion

The traceability matrix is a powerful tool that visualizes the relationships among user requirements, functional specifications, and extending through design, implementation, and testing. By properly utilizing this tool, requirement gaps and unnecessary function implementations can be prevented, and validation without excess or insufficiency can be achieved.

In system development, ensuring “build what should be built and do not build what should not be built” is actually extremely difficult, despite being seemingly obvious. The traceability matrix provides a systematic approach to this challenging task.

Particularly in the pharmaceutical and medical device industries, where patient safety and product quality directly impact human lives, the traceability matrix transcends being merely a management tool and becomes a cornerstone of quality assurance. When all development stakeholders understand this importance and maintain consistent traceability throughout the project, truly reliable system construction becomes possible.

As regulatory requirements continue to evolve globally, with initiatives such as the FDA’s QMSR adoption of ISO 13485:2016, the EU MDR’s stringent traceability mandates, and ongoing updates to IEC 62304, the importance of robust traceability practices will only increase. Organizations that invest in establishing effective traceability systems today will be better positioned to meet future regulatory challenges while delivering safer, higher-quality medical devices and systems.

The key to success is viewing traceability not as a compliance burden but as a fundamental quality engineering practice that provides value throughout the product lifecycle—from development efficiency through regulatory approval to post-market surveillance and continuous improvement.

Comment