Introduction

Technological innovation has been remarkable, with evolution from steam locomotives to bullet trains, and potentially to maglev trains in the future. However, in the world of sterilization, high-pressure steam sterilization (autoclaving) remains a primary sterilization method. High-pressure steam sterilization is widely used for the sterilization of medical devices, pharmaceutical containers, and reusable medical instruments because it is cost-effective, enables compact equipment design, and unlike ethylene oxide (EOG) sterilization, leaves no harmful residues.

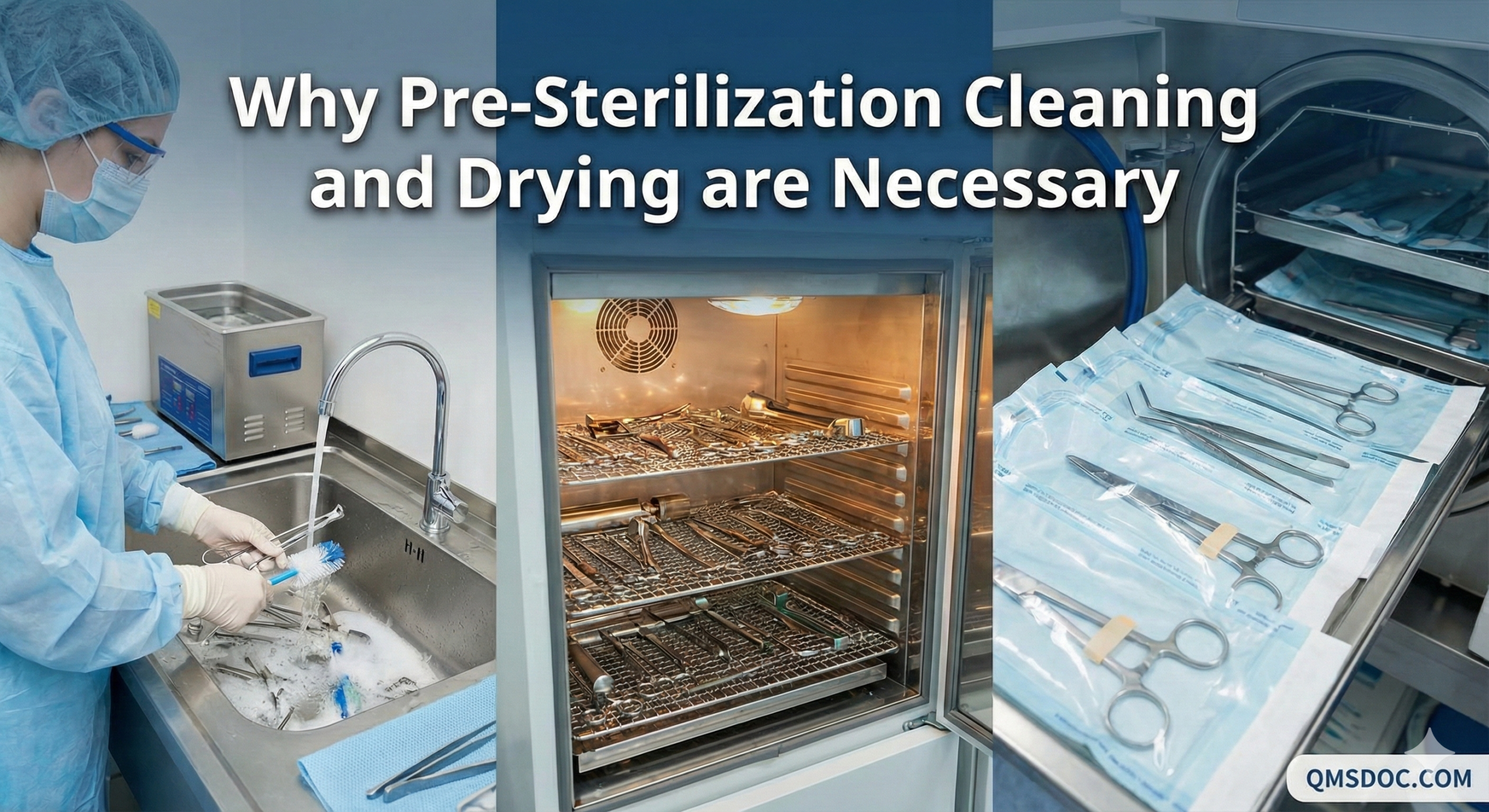

Pre-Sterilization Cleaning

The Importance of Bioburden

Pre-sterilization cleaning is extremely important not only for high-pressure steam sterilization but for all sterilization methods. The number and types of viable microorganisms present on items to be sterilized are referred to as “bioburden.” Bioburden measurement and control are critical criteria for manufacturing hygiene management required under Good Manufacturing Practice (GMP) standards.

Bioburden measurement methods are specified in ISO 11737-1:2018, “Sterilization of health care products – Microbiological methods – Part 1: Determination of a population of microorganisms on products.” This international standard was reconfirmed in 2023 and remains the current valid standard. Bioburden data provides essential information for the development, validation, and routine control of sterilization processes.

Microbial Reduction Through Cleaning

Appropriate cleaning can significantly reduce pre-sterilization bioburden. To ensure reliable disinfection and sterilization of medical devices and instruments, thorough preliminary cleaning is essential. The cleaning process serves as the first line of defense in effectively reducing microbial counts.

According to the literature, properly executed cleaning can reduce bioburden on instruments by approximately 3-4 logs (logarithmic reduction). This means microbial counts can be reduced by factors of 1,000 to 10,000. For example, bioburden starting at 10^6 (1,000,000) microorganisms can be reduced to 10^2 (100) through appropriate cleaning.

Impact on Sterilization Efficiency

As the microbial count decreases, the sterilization process can reach the Sterility Assurance Level (SAL) in a shorter time. For medical devices, a SAL of 10^-6 (a one-in-a-million probability that a viable microorganism remains) is generally required.

Since microbial inactivation proceeds exponentially (logarithmically), lower initial bioburden means less sterilization time and intensity are needed to achieve the target SAL. This is particularly significant for sterilizing heat-sensitive medical devices and pharmaceuticals.

ISO 17665:2024, “Sterilization of health care products – Moist heat – Requirements for the development, validation and routine control of a sterilization process for medical devices,” requires that sterilization process design take into account bioburden characteristics (number, type, and resistance).

Cleaning Validation and Monitoring

The cleaning process itself also requires validation. Cleaning validation must demonstrate that a specific cleaning method can consistently reduce bioburden to acceptable levels. Additionally, in manufacturing processes, periodic bioburden monitoring is required to continuously verify the effectiveness of cleaning processes.

European Medicines Agency (EMA) guidelines indicate that for aqueous solutions, a typical acceptable criterion for pre-sterilization bioburden limits is 100 CFU/100mL.

Pre-Sterilization Drying

The Importance of Drying

If items to be sterilized are wet before sterilization, sterilization failure may occur for the following reasons.

First, if items are initially wet, temperature rise during sterilization is hindered. Excess moisture absorbs latent heat during evaporation, potentially delaying or preventing the items from reaching the specified sterilization temperature.

Second, the sterilant (saturated steam in the case of high-pressure steam) cannot uniformly contact the items to be sterilized. Particularly when moisture accumulates in gaps or complex-shaped areas of instruments, steam penetration is obstructed, potentially resulting in inadequate sterilization of those areas.

Mechanism of Moist Heat Sterilization and the Role of Moisture

In high-pressure steam sterilization (moist heat sterilization), microorganisms are inactivated by the latent heat released when saturated steam contacts and condenses on the surface of items to be sterilized. In this process, the presence of appropriate moisture (steam) is essential. However, this refers to moisture from steam supplied during the sterilization process, which is different from excess moisture pre-adhered to items to be sterilized.

ISO 17665:2024 emphasizes that steam quality has a significant impact on sterilization efficacy. Ideal saturated steam should have dryness of 97% or higher (liquid content of 3% or less). Excessively wet steam (wet steam) or superheated steam can both reduce sterilization effectiveness.

The Problem of Wet Packs

A condition where moisture remains on packaging materials after sterilization is called a “wet pack.” Wet packs represent a significant recontamination risk. When moisture is present on the outside or inside of packaging materials, microorganisms from the environment can migrate into the sterilized product through the moisture via capillary action (wicking).

AAMI ST-79:2013 (Association for the Advancement of Medical Instrumentation steam sterilization standard) specifies that if moisture is observed on packaging materials at the end of the sterilization cycle, the product must be completely reprocessed. Similarly, if the sterilization cycle is interrupted or the specified drying time is not completed, the product must be reprocessed.

Validation of the Drying Process

In sterilization validation based on ISO 17665:2024, drying time is also an important validation parameter. Drying process validation must demonstrate that after the specified drying time, using the most difficult-to-dry products or packaging configurations (worst case), the moisture content of packaging materials is below acceptable levels.

For textile products, a general criterion is that weight gain after sterilization should be 1% or less, and for metal products, 0.2% or less (reference: ISO/TS 17665-2:2009 Annex A, EN 285).

Practical Measures to Promote Drying

In addition to appropriate drying before sterilization, measures to ensure drying after the sterilization cycle are also important.

In vacuum removal sterilizers (prevacuum type), a drying phase using HEPA-filtered air is incorporated in the final stage of the sterilization cycle. In contrast, gravity displacement sterilizers rely on evaporation from residual heat in the chamber walls, resulting in lower drying efficiency.

After sterilization, products must be properly cooled in a cooling area until they reach room temperature. Handling hot packaging can cause condensation, leading to wet packs. Additionally, stacking products during cooling can trap moisture and impede drying.

Summary

Pre-sterilization cleaning and drying are essential requirements for achieving effective sterilization.

Cleaning reduces bioburden by 3-4 logs, significantly improving sterilization process efficiency and enabling reliable achievement of sterility assurance levels in a shorter time. Appropriate cleaning also maximizes the effectiveness of sterilants by preventing residual organic matter (proteins, blood, etc.).

Drying is important both before and after sterilization. Appropriate pre-sterilization drying ensures uniform steam penetration and temperature achievement. Sufficient post-sterilization drying is essential to prevent recontamination from wet packs and maintain the sterility of sterilized products throughout their shelf life.

These processes must be appropriately validated and routinely monitored based on international standards and guidelines such as ISO 11737-1:2018 (bioburden determination), ISO 17665:2024 (moist heat sterilization), and AAMI ST-79 (steam sterilization in health care facilities).

Comment