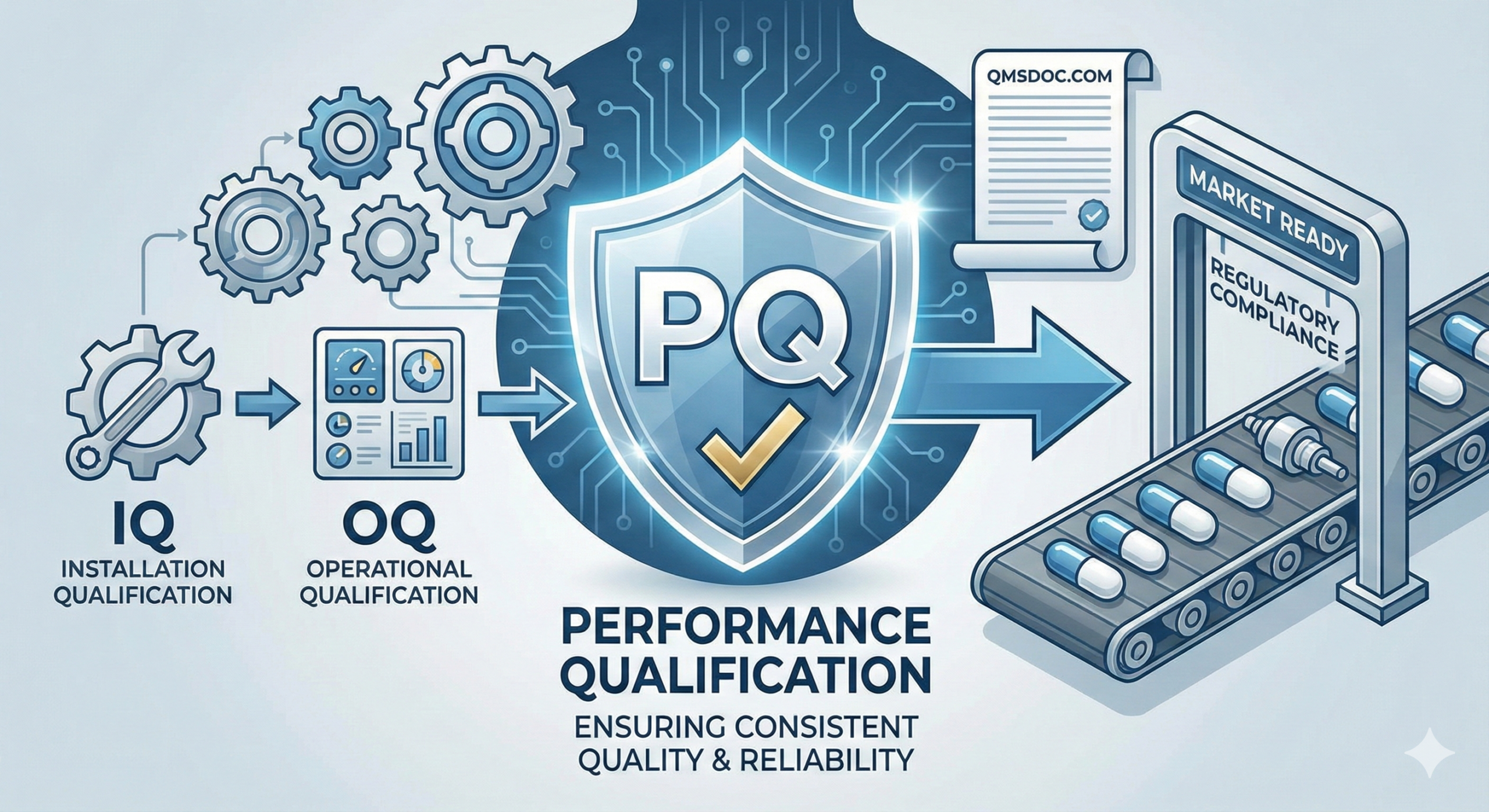

The Purpose of Performance Qualification (PQ)

Performance Qualification (PQ) is a critical activity conducted to establish a process’s capability to consistently produce products that meet specifications over an extended period. This goes beyond merely manufacturing three lots of product; it aims to scientifically demonstrate that a process can consistently produce specification-compliant products under normal operating conditions.

The term “performance” is often misunderstood. Performance here does not refer to processing speed or production capacity. Rather, it should be understood as “linearity” or “consistency.” True performance means the ability to manufacture the 10th lot, 100th lot, and 1,000th lot all with identical specifications and quality—in other words, the manufacturing process maintains stable quality over time.

Historical Background of PQ and the “Three-Lot” Concept

Historically, regulatory authorities such as the FDA recommended manufacturing at least three lots (or batches) for process validation. This “three-lot” concept originated from the FDA’s 1987 guideline “General Principles of Process Validation” and became established as an industry standard for many years.

The rationale for three lots emerged more from practical considerations than statistical ones. With only two lots, one can always draw a straight line between two points, but this does not prove true process stability. However, with data from three or more lots, one can statistically evaluate whether the results align linearly—that is, whether the process consistently produces quality products. In other words, success with one lot may be “incidental,” success with two consecutive lots may be “coincidental,” but success with three consecutive lots suggests “consistency.”

However, in today’s regulatory environment, the number “three lots” is no longer an absolute requirement. The FDA’s 2011 guidance “Process Validation: General Principles and Practices” redefined process validation as a lifecycle approach, clearly stating that the required number of lots should be scientifically determined based on process complexity, variability, and process understanding.

ICH Q7 (Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients) also states that “for prospective and concurrent validations, three consecutive successful production batches should be used as a guide, but there may be situations where additional process runs are warranted to prove consistency of the process,” explicitly indicating that three lots is a “guide” rather than an “absolute requirement.”

Definition of PQ in PIC/S GMP Annex 15

PIC/S GMP Annex 15 (2015 edition, latest revision) defines PQ as follows:

“Performance Qualification (PQ) is documenting that facilities, systems, and equipment, as connected together, can perform effectively and reproducibly, based on the approved process method and product specification.”

This definition emphasizes the need to demonstrate not merely that equipment operates, but that it can produce products of consistent quality following the approved manufacturing process.

Considerations for PQ Implementation

When conducting PQ, the following factors must be considered:

- Actual product and process parameters and methods established in OQ: Manufacturing actual products using the operating conditions established in OQ (Operational Qualification).

- Product specification acceptability: Confirming that manufactured products meet specified quality standards.

- Assurance of process capability established in OQ: Confirming that the process can perform as designed.

- Process reproducibility and long-term process stability: Demonstrating through multiple lots that the process produces consistent results.

In PQ, products are manufactured under actual production conditions established in OQ. Simultaneously, various action levels (control limits) and the content of Standard Operating Procedures (SOPs) are verified, and process assurance is further enhanced through repeated challenge testing.

Process Variation Management

Product and process data should be analyzed to determine the normal variation range within which process outputs remain within specification. Understanding the normal variation range clarifies whether the process is in a controlled state or within an acceptable range for manufacturing specific outputs. By reducing and managing variation, more advanced quality assurance can be achieved.

Depending on the characteristics and sensitivity of the process, variation factors to be controlled include:

- Temperature, humidity, equipment housing, condensation

- Power supply fluctuations, vibration, light

- Environmental contamination

- Process water purity

- Human factors (operator skill, fatigue, etc.)

- Raw material brand differences

- Physical property variations due to raw material lot changes (e.g., variations in stock solution viscosity affecting product removal performance)

Identifying and appropriately managing these variation factors is essential for ensuring process stability and product quality consistency.

Modern PQ Approach: Integrated Implementation

PIC/S GMP Annex 15 (2015 revision), Section 3.14, states that “PQ should normally follow the successful completion of IQ (Installation Qualification) and OQ. However, it may in some cases be appropriate to perform it in conjunction with OQ or Process Validation.”

Due to this provision, standalone PQ implementation has become less common, and integrated approaches are now frequently adopted:

- Concurrent implementation with OQ: Performance verification using actual products is conducted simultaneously with equipment operational performance confirmation.

- Integration with process validation: Particularly in the lifecycle approach introduced by the FDA’s 2011 Process Validation Guidance, PQ is implemented as part of Stage 2 activities called Process Performance Qualification (PPQ), as part of overall process validation.

Such integrated approaches not only improve efficiency but also deepen understanding of the entire process and enable more practical validation strategies.

Lifecycle Approach and PQ

The modern regulatory environment, particularly the FDA’s 2011 guidance and PIC/S GMP Annex 15, emphasizes process validation as a lifecycle approach. This approach categorizes validation activities into three stages:

Stage 1: Process Design

- The stage where commercial production processes are defined based on knowledge gained during product development and process development

Stage 2: Process Qualification/Performance Qualification

- The stage demonstrating that the designed process is reproducible and suitable for commercial manufacturing

- Activities corresponding to traditional PQ are included in this stage

Stage 3: Continued Process Verification

- The stage that continuously assures the process remains in a controlled state during routine manufacturing

In this lifecycle approach, PQ (or more contemporarily, PPQ) is positioned as a core element of overall process validation and should be understood not as a standalone activity but as part of a continuum from development through commercial manufacturing to continuous improvement.

Conclusion

PQ is a critical activity for scientifically demonstrating that a manufacturing process can consistently produce high-quality products over the long term. The field has evolved from the rigid “three-lot” concept of the past to a modern, scientific, and flexible approach based on process complexity, understanding, and risk.

Additionally, there is a shift from the traditional method of conducting PQ as a standalone activity to a modern approach of integrating it with OQ and overall process validation, requiring more efficient and practical validation strategies. Understanding the lifecycle approach to process validation and implementing appropriate activities at each stage is essential for meeting modern GMP requirements.

Summary Table: Evolution of PQ Approach

| Aspect | Traditional Approach (Pre-2011) | Modern Lifecycle Approach (Post-2011) |

| Number of lots | Fixed at 3 lots as standard | Determined scientifically based on risk, complexity, and process understanding |

| Implementation timing | After completion of OQ | Can be concurrent with OQ or integrated with process validation |

| Terminology | PQ (Performance Qualification) | PPQ (Process Performance Qualification) as Stage 2 of validation lifecycle |

| Scope | Discrete validation event | Part of continuous lifecycle from development through commercial manufacturing |

| Documentation focus | Emphasis on final documentation | Emphasis on Stage 1 understanding and Stage 3 continuous monitoring |

| Justification basis | Rule-based (3 consecutive lots) | Science-based and risk-based approach |

| Validation type | Prospective, concurrent, or retrospective | Lifecycle approach (retrospective validation no longer acceptable) |

| Regulatory basis | FDA 1987 guideline, PIC/S GMP Annex 15 (pre-2015) | FDA 2011 guidance, PIC/S GMP Annex 15 (2015 revision), ICH Q7, Q8, Q10, Q11 |

This table illustrates the fundamental shift in regulatory thinking and industry practice regarding performance qualification, reflecting the move toward more scientific, risk-based, and integrated approaches to ensuring pharmaceutical quality.

Comment