The Critical Importance of Root Cause Analysis

Root Cause Investigation and Recurrence Prevention: The Foundation of Quality Management

A Historical Lesson: The Japan Airlines Flight 123 Tragedy

On August 12, 1985, Japan Airlines Flight 123, a Boeing 747SR-100 aircraft (registration JA8119), departed from Haneda Airport at 18:12 (local time) bound for Itami Airport in Osaka. Twelve minutes after takeoff, a catastrophic failure occurred, leading to 32 minutes of uncontrolled flight before the aircraft crashed in the mountains of Ueno Village, Tano District, Gunma Prefecture.

Of the 524 people on board (509 passengers and 15 crew members), 520 precious lives were lost, with only four survivors. This remains the deadliest single-aircraft accident in aviation history and Japan’s worst aviation disaster.

The investigation concluded that the crash was caused by improper repair of the aft pressure bulkhead by Boeing Corporation following a tail strike incident seven years earlier in 1978. The faulty repair involved incorrect riveting procedures during the bulkhead’s repair, which led to metal fatigue and eventual catastrophic failure during flight.

The Role of Criminal Liability in Safety Investigations

The approach to criminal liability in aviation accidents varies significantly across jurisdictions, with important implications for safety investigations and root cause analysis.

In the United States, the aviation safety system emphasizes learning from accidents rather than punitive measures. While criminal prosecution is possible under both federal and state laws, particularly in cases involving gross negligence, willful misconduct, or criminal intent, the system generally prioritizes thorough investigation and prevention over criminalization of honest errors.

The Federal Aviation Administration (FAA) and National Transportation Safety Board (NTSB) have established several programs designed to encourage reporting and cooperation in safety investigations. These include:

- Aviation Safety Reporting System (ASRS): Provides limited immunity from administrative action for voluntary reporting

- Aviation Safety Action Program (ASAP): Offers immunity for self-disclosure of safety concerns

- Flight Operations Quality Assurance (FOQA): Protects routine flight data sharing from punitive use

The underlying philosophy recognizes that approximately 75% of aviation accidents involve some form of human error, and that criminalizing such errors discourages the open reporting essential for effective root cause analysis. When individuals fear criminal prosecution, they are less likely to provide complete and accurate information during investigations, potentially hindering the discovery of systemic issues and preventing the implementation of effective corrective actions.

This approach stands in contrast to systems that emphasize criminal accountability, where the threat of prosecution may lead to concealment of evidence, reluctance to testify, and incomplete investigations—ultimately compromising the ability to prevent future accidents.

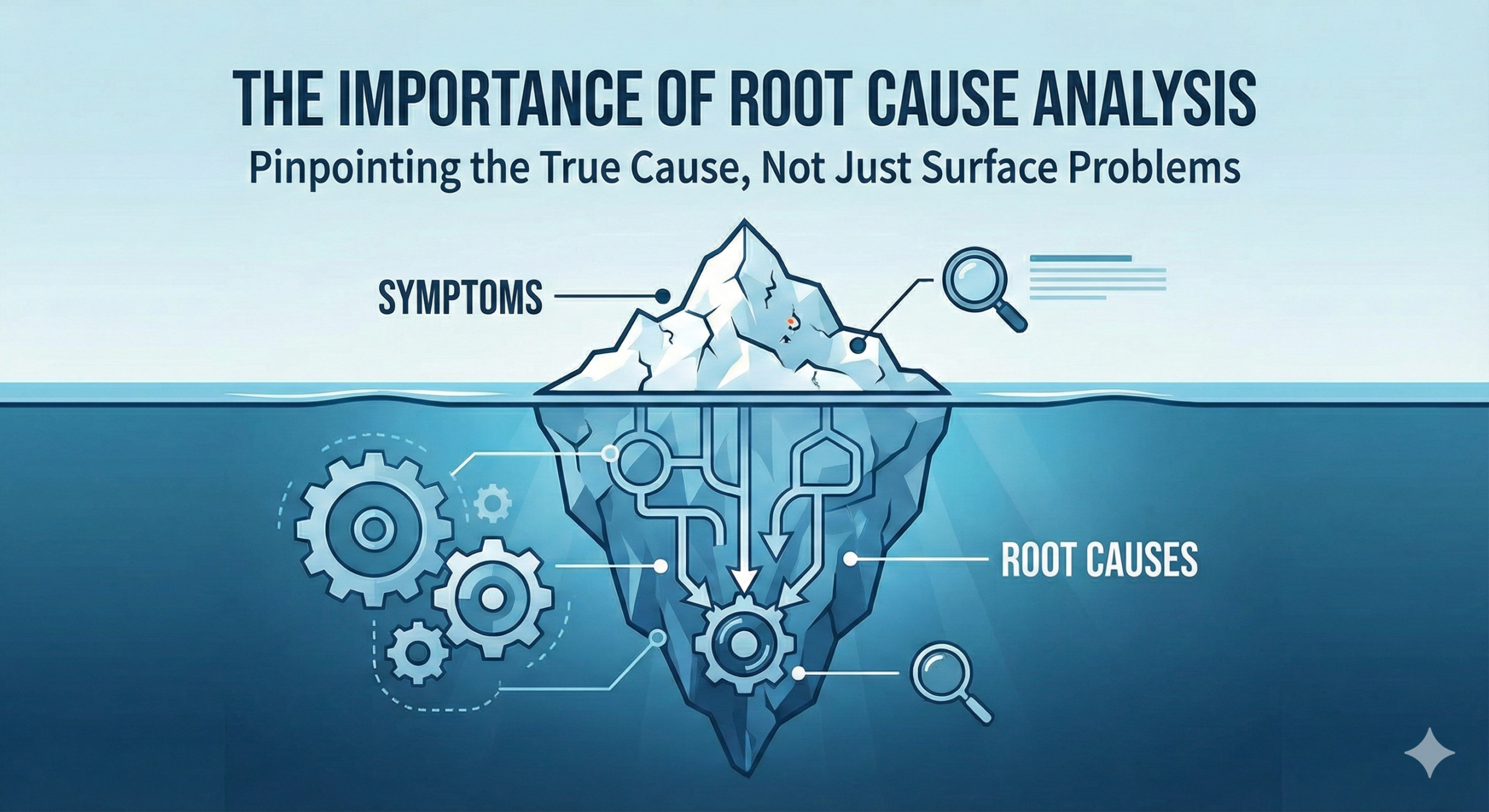

The Fundamental Importance of Root Cause Analysis

While the occurrence of any accident is deeply regrettable, the paramount objective must be to prevent its recurrence. This cannot be achieved without thorough and systematic identification of the root cause.

If the root cause remains undiscovered or unaddressed, similar accidents will inevitably recur. The tragedy of the JAL 123 accident underscores this principle—had the original repair been properly executed or its inadequacy discovered through systematic quality controls, 520 lives could have been saved.

Understanding Root Cause and Implementing Corrective Actions

The Concept of Root Cause in CAPA Systems

Corrective and Preventive Action (CAPA) is a fundamental quality system requirement mandated by regulatory authorities worldwide for medical device manufacturers. The core principle of any effective corrective action is the elimination of the root cause.

When addressing a nonconformity or quality problem, the first essential step is to investigate and identify the underlying root cause. However, determining the true root cause is rarely straightforward and requires systematic analysis and appropriate methodology.

Regulatory Framework for CAPA

Medical device manufacturers must comply with comprehensive CAPA requirements established by multiple regulatory bodies:

United States – FDA Requirements:

- 21 CFR Part 820.100 mandates establishment and maintenance of procedures for implementing corrective and preventive action

- Requirements include analysis of processes, work operations, quality audit reports, complaints, and other quality data sources

- CAPA is consistently the #1 citation in FDA 483 observations and warning letters

International Standards:

- ISO 13485:2016 (Medical devices – Quality management systems):

- Section 8.5.2 addresses corrective action requirements

- Section 8.5.3 covers preventive action requirements

- Requires organizations to investigate nonconformities, implement actions to prevent recurrence, and evaluate effectiveness

European Union Requirements:

- EU Medical Device Regulation (MDR 2017/745) and In Vitro Diagnostic Regulation (IVDR 2017/746) require manufacturers to document corrective and preventive actions as part of post-market surveillance

- MDCG 2024-12 Guidance provides detailed templates for CAPA plans and emphasizes comprehensive approaches to eliminating root causes

Common Pitfalls in Root Cause Identification

Through extensive experience conducting CAPA training and consulting for medical device companies, a recurring observation is that many practitioners struggle to correctly identify root causes. The most common error is confusing immediate causes or contributing factors with the actual root cause.

Frequently Encountered Incorrect “Root Causes”:

| Incorrect Statement | Why This Is Not a Root Cause | True Root Cause Direction |

| “Training was insufficient” | Addresses symptom, not system | Why was training insufficient? What systemic gap allowed inadequate training? |

| “There was lack of understanding/awareness” | Focuses on individual failure | What system failed to ensure understanding? What controls were missing? |

| “The operator thought/assumed…” | Blames individual perception | What systemic ambiguity or inadequate documentation allowed misunderstanding? |

| “The procedure was not followed” | Identifies deviation, not cause | Why was deviation possible? What systemic control failed? |

These statements identify problems but do not constitute root causes. The most common mistake in root cause analysis is stopping at human factors or individual product issues rather than investigating the underlying systemic failures.

Why Individual-Focused Corrective Actions Fail

Corrective actions that target only individual factors (such as personal discipline, attention, or awareness) or focus solely on a specific product unit will inevitably lead to recurrence.

Consider this example: A corrective action states: “We will reinforce training and issue strict warnings to prevent recurrence.”

Why this approach is inadequate:

- The individual who received training or warnings may not repeat the error

- However, in any organization, personnel turnover is inevitable

- When new personnel join, they lack the benefit of the previous incident experience

- Without systematic controls, the same error will likely recur with different individuals

- The organizational knowledge is not captured in the quality management system (QMS)

The fundamental truth about human nature: Human beings are inherently prone to distraction, fatigue, and error. Quality systems that rely solely on human discipline, vigilance, or attention cannot maintain consistent quality indefinitely. Eventually, somewhere, someone will make a similar mistake.

The CAPA Philosophy: Systematic Prevention

Identifying Systemic Deficiencies

The essence of effective corrective action is addressing systemic deficiencies within the Quality Management System (QMS), specifically:

- Gaps in procedures or work instructions

- Weaknesses in design controls or process validations

- Inadequacies in verification or validation activities

- Contradictions between different procedures or requirements

- Ambiguities in documentation that permit multiple interpretations

- Missing controls or checkpoints in critical processes

Building Recurrence Prevention into the System

True prevention of recurrence is achieved only when corrective actions are integrated into the organizational QMS as institutional knowledge and systematic controls. This transforms individual learning into organizational capability.

The objective is to construct a system with built-in checks and controls that prevent errors from occurring or detect them before they result in nonconforming products or quality escapes. This is far more reliable than depending on human vigilance alone.

Key principle: The goal is to build methodology that reliably prevents customer complaints, nonconformities, errors, and losses by embedding controls directly into the QMS, making quality automatic rather than dependent on individual performance.

Methodologies for Root Cause Analysis

The Critical Nature of Thorough Investigation

Effective root cause elimination requires comprehensive investigation of all potential causal factors. Proper identification and specification of causes is indispensable to successful corrective action. Without rigorous cause investigation, meaningful corrective action is impossible.

The fundamental question that must be answered is: “Why did this situation occur?”

This seemingly simple question often requires multiple iterations and systematic analysis using appropriate tools.

Principal Root Cause Analysis Methods

The selection of analytical tools should be based on the nature and complexity of the problem being investigated. Common and effective methodologies include:

1. Five Whys Analysis (5 Whys / Why-Why Analysis)

- Description: An iterative interrogative technique that explores cause-and-effect relationships by repeatedly asking “Why?” (typically five times, though the actual number may vary)

- Best applied to: Relatively straightforward problems with clear cause-and-effect chains

- Advantages: Simple, requires no special tools, can be performed quickly

- Limitations: May oversimplify complex problems; effectiveness depends on the investigator’s knowledge

- Example application:

- Problem: Medical device component detachment

- Why #1: Adhesive bond failed

- Why #2: Adhesive was applied inconsistently

- Why #3: Dispenser settings were incorrect

- Why #4: No verification procedure for dispenser calibration

- Why #5 (Root Cause): QMS lacked documented procedure for equipment calibration verification

2. Fishbone Diagram (Ishikawa Diagram / Cause-and-Effect Diagram)

- Description: A visual tool that systematically identifies multiple potential causes by categorizing them (typically: Man, Machine, Material, Method, Measurement, Environment)

- Best applied to: Complex problems with multiple contributing factors

- Advantages: Facilitates team brainstorming, provides comprehensive view, visual organization

- Limitations: Can become overwhelming if not properly focused; doesn’t prioritize causes

- Key to success: Requires cross-functional team participation (minimum 3 people)

3. Failure Mode and Effects Analysis (FMEA)

- Description: A systematic, proactive method for evaluating processes or products to identify where and how they might fail

- Components: Analyzes Severity, Occurrence, and Detection to calculate Risk Priority Number (RPN)

- Best applied to: Design phase issues, manufacturing process analysis, singular failure events

- Advantages: Quantifies risk, prioritizes action items, proactive approach

- Limitations: Less effective for use-phase issues with multiple contributing factors; time-intensive

- Critical note: FMEA is particularly powerful for design and manufacturing issues but may be less suitable for complex field failures involving multiple variables

4. Fault Tree Analysis (FTA)

- Description: A top-down, deductive analytical method using Boolean logic to identify potential causes of system failures

- Process: Starts with an undesired event and systematically traces all possible contributing factors using AND/OR logic gates

- Best applied to: Complex system failures, safety-critical applications, post-market device failures

- Advantages: Rigorous logical structure, identifies single points of failure, effective for complex systems

- Why FTA is particularly powerful: For solving design problems, manufacturing issues, and especially post-market field failures involving multiple interacting factors, FTA provides the most comprehensive analytical framework

- Application example: Analyzing why an insulin pump delivered incorrect dosage by mapping all possible hardware, software, and environmental contributors

5. Additional Complementary Methods:

- KJ Method (Affinity Diagram): Groups large numbers of ideas into natural relationships

- Pareto Analysis: Applies the 80/20 rule to identify the vital few causes from the trivial many

- Scatter Plots: Visualizes relationships between variables

- Hypothesis Testing: Uses statistical methods to validate suspected root causes

The Critical Importance of Investigation Methodology: A Common Deficiency

A particularly concerning practice observed in medical device companies involves inadequate investigation of customer complaints, specifically the failure to conduct reproduction experiments.

The Reproduction Experiment Problem:

Many companies, upon receiving complaints about device failures or malfunctions, fail to systematically attempt to reproduce the reported problem. Instead, they:

- Make superficial inspections

- Repair the obvious defect

- Return the device to the customer

- Close the complaint without identifying root cause

Consequences of this inadequate approach:

- Root cause remains unknown: Without reproduction, the true mechanism of failure cannot be understood

- Recurrence is inevitable: The same failure will occur again in other units

- Customer trust erodes: Repeated failures demonstrate inadequate quality systems

- Regulatory exposure increases: FDA and other regulators view inadequate investigations as serious QMS deficiencies

The proper approach requires:

- Systematic reproduction attempts: Design experiments to recreate the failure conditions

- Comprehensive data collection: Gather device history records, environmental conditions, use patterns

- Failure analysis: Conduct appropriate testing (electrical, mechanical, software, materials analysis)

- Root cause determination: Only after successful reproduction can true root cause be identified

- Systemic correction: Implement QMS changes to prevent recurrence across all products

When reproduction is impossible despite reasonable efforts, companies must:

- Document all attempts and rationale

- Analyze similar complaints for patterns

- Consider implementing preventive actions based on suspected causes

- Continue monitoring for additional data

Regulatory perspective: Inadequate root cause investigations are among the most frequently cited deficiencies in FDA inspections and warning letters. Companies with persistent customer complaints often exhibit systematic failures in their CAPA investigation processes.

Integration of Root Cause Analysis with Quality Management Systems

The CAPA Process Within QMS

Effective CAPA systems do not operate in isolation but integrate with multiple QMS subsystems:

Input Sources for CAPA:

- Customer complaints and feedback

- Internal audit findings

- Nonconformance reports

- Management review outputs

- Design and development verification/validation failures

- Process monitoring and measurement data

- Supplier quality issues

- Post-market surveillance data

- Risk management activities

Output Integration:

- Design control updates

- Process validation revisions

- Training program modifications

- Supplier quality requirements

- Risk management file updates

- Post-market surveillance protocols

- Document and procedure revisions

Verification of CAPA Effectiveness

Regulatory requirements mandate that all corrective and preventive actions must be verified for effectiveness. This verification must:

- Be planned: Define specific criteria for measuring effectiveness

- Be timely: Occur after sufficient time for implementation but before closure

- Use objective evidence: Rely on data rather than opinion

- Consider adequacy: Ensure the action addresses the root cause

- Prevent adverse impact: Confirm the action doesn’t negatively affect other processes or products

Verification methods include:

- Trend analysis of relevant quality metrics

- Re-auditing affected processes

- Review of subsequent customer complaints

- Process capability studies

- Design verification testing

Practical Implementation Guidance

Building an Effective CAPA Culture

1. Leadership Commitment:

- Management must view CAPA as a strategic quality improvement tool, not merely a regulatory requirement

- Allocate adequate resources for thorough investigations

- Foster a “no-blame” culture that encourages reporting and open discussion

2. Cross-Functional Investigation:

- Root cause analysis benefits enormously from diverse perspectives

- Include representatives from quality, engineering, manufacturing, service, and regulatory

- External expertise may be valuable for complex technical investigations

3. Appropriate Tool Selection:

- Match the analytical tool to the problem complexity

- Start with simpler methods (5 Whys, Fishbone) for straightforward issues

- Apply more sophisticated techniques (FTA, FMEA) for complex or critical problems

- Don’t let the tool become an impediment—the goal is finding root cause, not perfect documentation

4. Documentation Requirements:

- Maintain complete records of investigation process and findings

- Document all considered root causes, not only the final determination

- Record the rationale for selected corrective actions

- Ensure traceability to effectiveness verification

5. Timeliness Balance:

- Respond promptly to prevent continued impact

- Allow sufficient time for thorough investigation

- Don’t sacrifice quality of investigation for speed of closure

- Consider interim containment actions while root cause investigation continues

Measuring CAPA System Performance

Organizations should monitor CAPA system effectiveness through metrics such as:

- Time from identification to corrective action implementation

- Recurrence rate of similar nonconformities

- Percentage of CAPAs requiring revision or extension

- Effectiveness verification pass rate

- Quality trend improvements in affected processes

- Reduction in customer complaints

Conclusion

The JAL Flight 123 tragedy serves as a profound reminder that inadequate root cause analysis and insufficient corrective action can have devastating consequences. While most quality failures in medical devices do not result in loss of life on such a scale, the principle remains the same: only through rigorous, systematic root cause analysis and comprehensive systemic corrective action can we prevent recurrence and continuously improve product quality and patient safety.

The investment in proper root cause analysis methodologies, adequate investigation resources, and systematic CAPA implementation is not merely a regulatory compliance exercise—it is a fundamental ethical and business imperative. Organizations that excel at root cause analysis and systemic correction build sustainable competitive advantages through superior quality, reduced costs, and enhanced customer trust.

Key Takeaways:

- Root causes are systemic, not individual—effective CAPA addresses QMS deficiencies

- Multiple analytical tools exist; selection should match problem complexity

- Reproduction experiments are critical for understanding failure mechanisms

- Effectiveness verification is mandatory and must use objective evidence

- CAPA systems must integrate throughout the QMS, not operate in isolation

- Regulatory compliance depends on demonstrating comprehensive, thorough investigations

- Organizational culture supporting open reporting is essential for effective root cause analysis

By embracing these principles and maintaining unwavering commitment to systematic root cause elimination, medical device manufacturers can fulfill their responsibility to patients, healthcare providers, and society while building robust, sustainable quality management systems.

This article provides guidance on root cause analysis and CAPA principles for medical device manufacturers. For specific regulatory requirements applicable to your products and markets, consult the relevant regulations (21 CFR Part 820, ISO 13485:2016, EU MDR/IVDR) and seek appropriate regulatory expertise.

Comment