Understanding Good Manufacturing Practice (GMP) for Health Foods

In modern society, health foods and dietary supplements have become indispensable parts of many people’s daily lives. However, consumers have limited means of knowing whether these products are manufactured safely and maintained at a consistent quality level. Health Food GMP is a manufacturing standard designed to address this challenge, serving as an important indicator for consumers to select health foods with confidence. This article provides an accessible explanation of everything from the basic concepts of Health Food GMP to the latest developments in the field.

What is GMP?

GMP (Good Manufacturing Practice) refers to standards established to ensure quality and safety in the manufacturing of products related to human health and safety. Health Food GMP is a standard established by the Ministry of Health, Labour and Welfare (MHLW) of Japan to prevent quality variations and contamination or adulteration with harmful substances during the manufacturing process of health foods. Its purpose is to manage all processes from receiving raw materials through manufacturing to shipping, ensuring that products are made “safely” and that “consistent quality” is guaranteed.

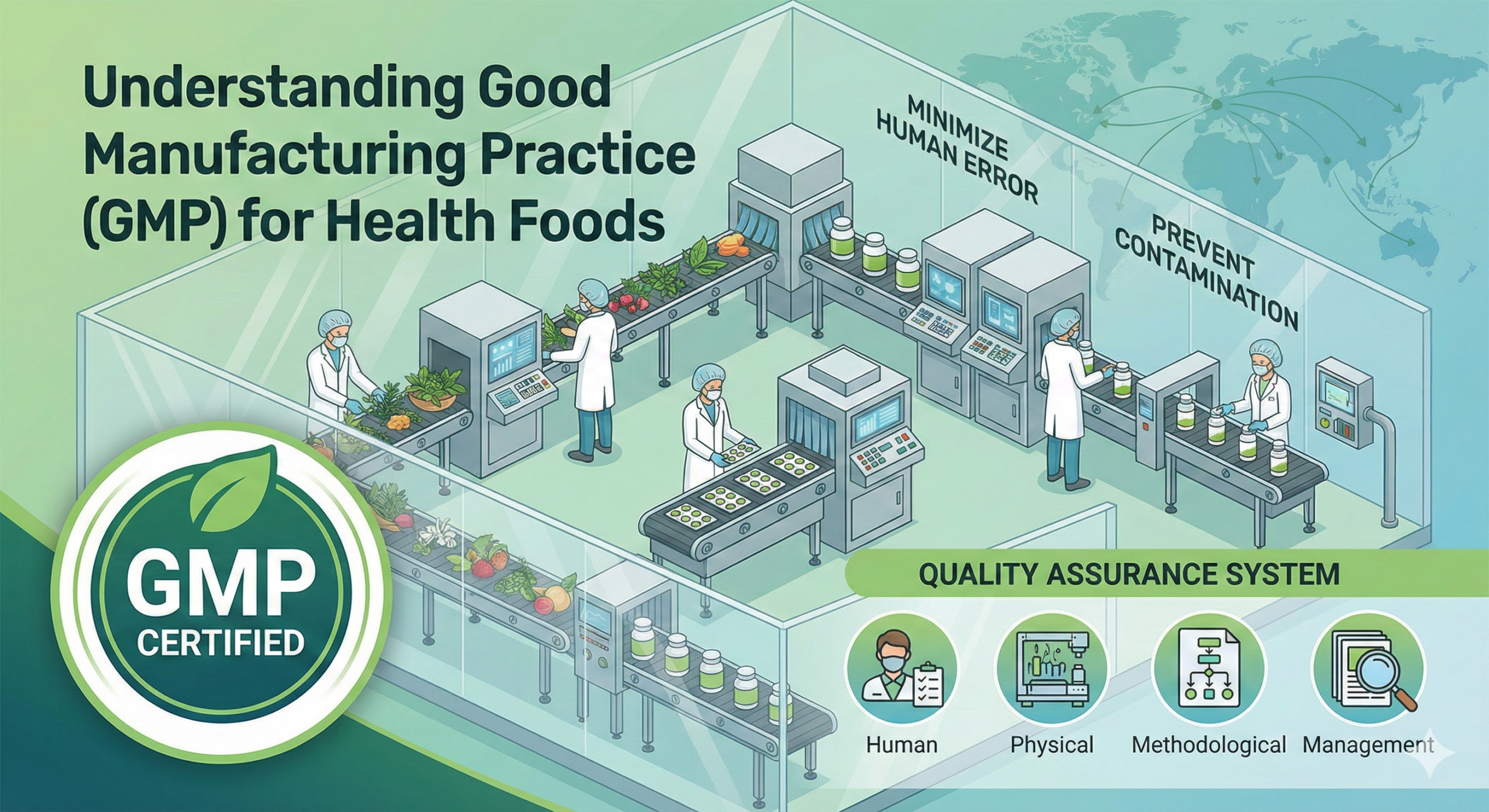

The Three Principles of GMP

Health Food GMP is based on the following three principles:

- Minimizing human error

- Preventing product contamination and quality degradation

- Designing systems that guarantee high quality

To satisfy these principles, guidelines are provided for both soft aspects such as employee education and management, and hard aspects such as the layout of facilities and equipment.

Differences Between Pharmaceutical GMP and Health Food GMP

The positioning of GMP differs significantly between pharmaceuticals and health foods. Pharmaceutical GMP was promulgated as a ministerial ordinance by the Ministry of Health and Welfare in 1980 and became a requirement for pharmaceutical manufacturing licenses in 1994. In contrast, Health Food GMP was introduced through a notification from the Ministry of Health, Labour and Welfare in 2005 but remained a “recommendation” for an extended period without legal enforcement.

While health foods are subject to mandatory hygiene management under HACCP (Hazard Analysis and Critical Control Points) based on the Food Sanitation Act, quality control (GMP) has been outside the scope of legal regulation and left to the voluntary efforts of manufacturing businesses. However, in response to recent health hazard issues, it has been decided that GMP will become mandatory for Foods with Function Claims (FFCs) in supplement form starting September 2026.

Table 1: Comparison of Pharmaceutical GMP and Health Food GMP

| Item | Pharmaceutical GMP | Health Food GMP |

| Legal Basis | Ministerial Ordinance (Pharmaceutical Affairs Act) | MHLW Notification → Will become mandatory (September 2026) |

| Implementation Year | 1980 (promulgated), 1994 (made mandatory) | 2005 (guidance), 2026 (mandatory for FFCs in supplement form) |

| Regulatory Authority | Pharmaceuticals and Medical Devices Agency (PMDA) | Consumer Affairs Agency, MHLW |

| Current Status | Mandatory (license requirement) | Voluntary → Partially mandatory (from September 2026) |

| Scope of Application | All pharmaceutical products | Foods with Function Claims (supplement form), voluntary for others |

Health Food GMP Certification Bodies and Standards

The two main organizations conducting Health Food GMP certification in Japan are:

- Japan Health and Nutrition Food Association (JHNFA)

- Japan Institute of Health Food Standards (JIHFS)

These two organizations audit and certify health food manufacturing facilities based on the basic requirements of the MHLW’s “Health Food GMP Guidelines.” Health Food GMP broadly consists of two categories: raw material processes and product processes. In recent years, GMP certification for imported raw materials has also begun.

Management System for Health Food GMP

Health Food GMP consists of the following four elements:

1. Human Elements

Thorough education, training, and hygiene management of manufacturing personnel are implemented, and the responsibilities and authorities of workers are clarified to prevent errors. This includes health checks, handwashing, and wearing appropriate work clothing.

2. Physical Elements

Design, cleaning, maintenance, and prevention of cross-contamination of manufacturing facilities and equipment are thoroughly conducted. Regular calibration of equipment and machinery is performed to maintain a consistently accurate manufacturing environment.

3. Methodological Elements

SOPs (Standard Operating Procedures) are developed to standardize processes. Additionally, process validation is conducted to confirm the effectiveness of manufacturing methods.

4. Management Elements

Manufacturing records and document management are thoroughly maintained to ensure traceability. Regular internal audits are conducted to identify issues and implement corrective measures.

Through these initiatives, product quality is consistently managed “from the planning stage to the shipping stage.”

Process for Obtaining GMP Certification

To obtain Health Food GMP conformity certification, it is necessary to apply to a certification body and undergo rigorous examination. The process is as follows:

- Submission of certification application (prerequisite: “approximately 3 months of management experience based on GMP”)

- Document investigation by investigators

- Improvement of issues identified in document investigation

- On-site investigation by investigators

- Improvement of issues identified in on-site investigation

- Examination by GMP Factory Certification Review Committee

- Certification

This certification process is rigorous, with investigations and examinations taking approximately 6 months to 1 year. Furthermore, since the certification period is 3 years, renewal applications are required every 3 years to maintain certification.

GMP Mark and Providing Assurance to Consumers

Products manufactured at Health Food GMP-certified factories can bear the “GMP Mark.” This mark is proof that the product has been safely manufactured in all processes from receiving raw materials through manufacturing to shipping, indicating that consistent quality is guaranteed.

When selecting health foods, consumers can use this GMP mark as a guide to consume products with greater peace of mind.

Recent Developments and Future Outlook

GMP Mandatory Implementation

In response to health hazard issues caused by Foods with Function Claims that occurred in 2024, the Consumer Affairs Agency decided to make GMP mandatory for products in supplement form under the Foods with Function Claims system. From September 1, 2026, this will be legally mandated, strengthening the assurance of product safety and quality.

Important Note: As of January 2026, the industry is in the final preparation phase for this mandatory implementation. Manufacturing businesses that produce Foods with Function Claims in supplement form must complete their GMP certification acquisition by the deadline.

Strengthening of Raw Material GMP

Certification bodies are advancing the strengthening of raw material GMP. In particular, GMP certification for imported raw materials has commenced, with requirements including conducting analytical testing domestically for each manufacturing lot of imported raw materials.

Enhanced Management of Microbial-Related Raw Materials

At the end of 2024, regulations concerning the manufacturing and quality control of supplements using “raw materials produced through cultivation or fermentation processes of microorganisms, including algae” were newly incorporated, requiring more stringent management.

Consistency with International GMP Requirements

For overseas expansion of health foods, Health Food GMP is an essential condition. GMP is mandated under the United States’ “Dietary Supplement Health and Education Act (DSHEA),” the EU’s “Food Supplements Directive,” and ASEAN’s “Health Supplement Regulations,” making international consistency an important issue.

Table 2: International GMP Requirements for Health Foods/Dietary Supplements

| Country/Region | Regulation | GMP Status | Key Features |

| United States | DSHEA (Dietary Supplement Health and Education Act) | Mandatory (cGMP regulations by FDA) | Applies to all dietary supplement manufacturers |

| European Union | Food Supplements Directive | Voluntary at EU level, mandatory in some member states | Each member state may have additional requirements |

| ASEAN | ASEAN Health Supplement Product Directive | Mandatory in member countries | Harmonized standards across ASEAN region |

| Japan | Food Sanitation Act, Foods with Function Claims system | Mandatory for FFCs (supplement form) from Sept. 2026 | Previously voluntary, becoming mandatory |

| Australia | Therapeutic Goods Act | Mandatory (Code of GMP) | Applies to complementary medicines |

Summary

Health Food GMP is an important standard for ensuring the quality and safety of health foods. With the mandatory implementation of GMP for Foods with Function Claims starting in September 2026, Japan’s health food industry quality control system is expected to be further strengthened.

When selecting health foods, consumers can use the GMP mark as a guide to consume products with greater confidence. For manufacturing businesses as well, obtaining GMP certification leads to improved product credibility and differentiation, providing significant business advantages.

The assurance of safety and quality of health foods is emphasized both domestically and internationally, and it is expected that GMP standards will continue to evolve. Both consumers and manufacturers need to pay attention to these developments.

Key Points for Consumers

When purchasing health foods and supplements, consider the following points:

- Look for the GMP mark on product packaging or manufacturer websites

- Check whether the manufacturer’s facilities are GMP-certified

- For Foods with Function Claims in supplement form, GMP certification will become mandatory from September 2026

- The GMP mark indicates that the product has been manufactured under controlled conditions throughout all processes

- GMP certification is renewed every 3 years, so check that the certification is current

Key Points for Manufacturing Businesses

For businesses involved in health food manufacturing, the following points are important:

- If manufacturing Foods with Function Claims in supplement form, GMP certification must be obtained by September 2026

- The certification acquisition process takes approximately 6 months to 1 year

- At least 3 months of management experience based on GMP is required before application

- Certification requires renewal every 3 years

- Both documentation systems and physical manufacturing environments must meet standards

- For overseas expansion, international GMP compliance is essential

- Enhanced management of raw materials, especially imported materials, is becoming increasingly important

The evolution of Health Food GMP standards represents a significant step forward in consumer protection and industry quality assurance. As the mandatory implementation date approaches, all stakeholders in the health food industry must prepare accordingly to meet these enhanced requirements.

Comment