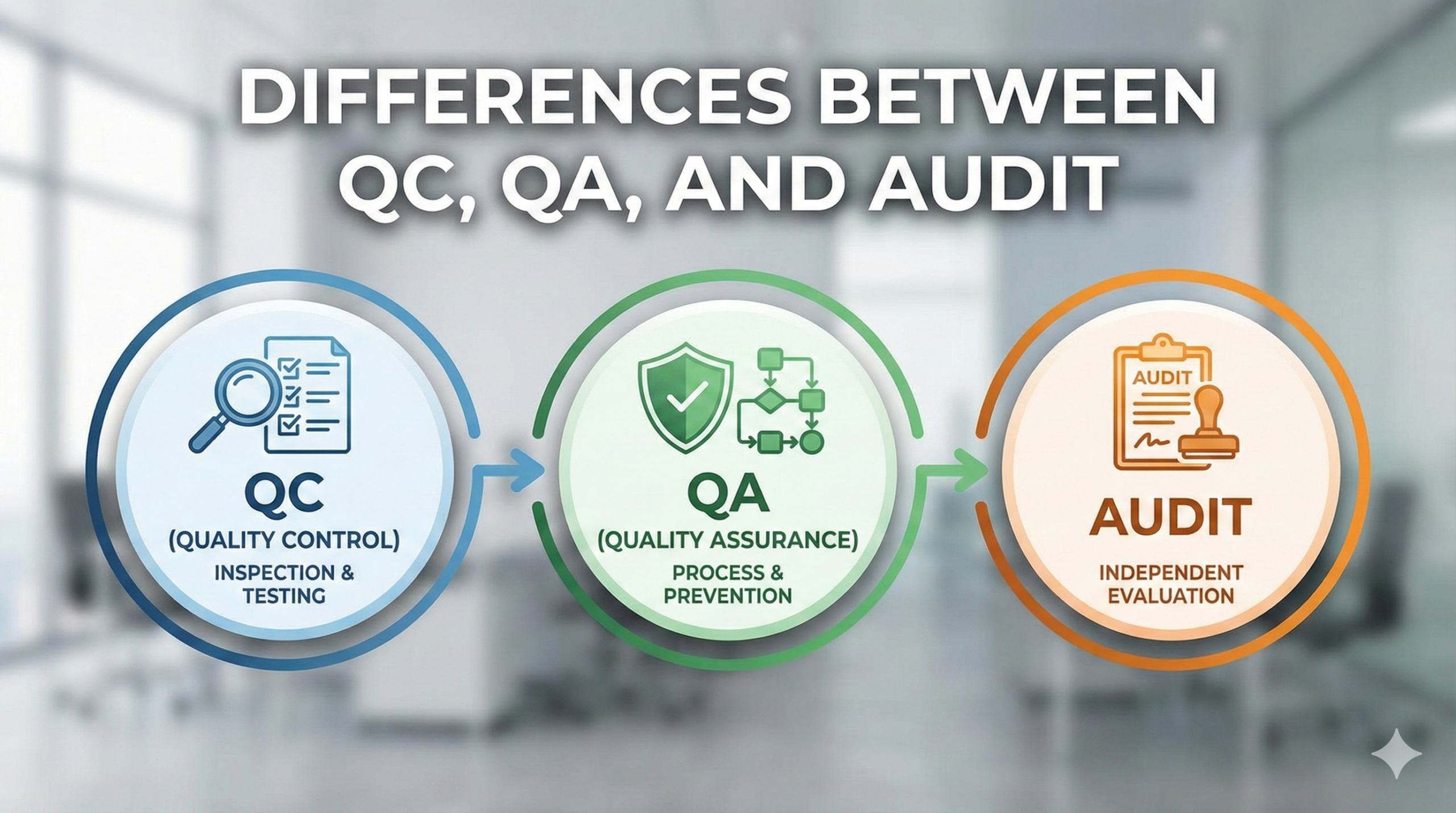

Differences Between QC, QA, and Audit

In the previous discussion, we clarified the concept of quality. Now, we will examine Quality Control (QC), Quality Assurance (QA), and auditing. These are critically important processes in ensuring quality, and each has distinctly different roles and responsibilities. Accurately understanding these differences forms the foundation of effective quality management.

Quality Control (QC)

First, let us consider Quality Control.

Here is an important question: Is your organization truly “controlling” quality? In my experience conducting audits and consultations at numerous pharmaceutical companies, I frequently observe organizations that merely perform “checks.” However, it is crucial to understand that QC is not simply “checking” but rather “control” or “management.”

Why do we use the term “control”? This is the first thing we should consider.

To understand control, imagine a baseball pitcher. The pitcher aims for the strike zone, observes the result, and adjusts the next pitch accordingly. Similarly, QC is a series of activities involving “measurement,” “evaluation,” and “adjustment” of products or processes. In other words, it encompasses the entire activity of running the PDCA (Plan-Do-Check-Act) cycle for continuous improvement, not merely checking and discovering problems.

The characteristics of QC are as follows: QC is an activity where individuals manage quality themselves, as exemplified by self-inspection. Therefore, having others perform QC is not its original intended form. Each person must properly manage their own work.

Quality Assurance (QA)

Next, let us examine QA, which stands for Quality Assurance.

What exactly is “Assurance”? This is an extremely important and comprehensive concept. QA is “a systematic activity that ensures products or services meet predetermined quality standards.” It involves establishing and operating a quality assurance system from a long-term, holistic perspective, covering everything from the planning stage of products through post-sales follow-up.

The characteristics of QA are as follows: QA personnel do not necessarily need to be in a separate department. Rather, QA should be deeply involved in the relevant processes, ensuring quality while operations continue. It is naturally appropriate for individuals to control their own work, manage quality themselves, and provide their own assurance. Therefore, quality assurance can be performed by those belonging to the relevant department. It is highly beneficial for individuals to assure the quality of their own work.

However, QA takes a broader view than QC and represents more systematic and organizational activities to ensure quality. In most cases, QC is encompassed within QA.

Audit

Finally, let us discuss auditing. Another source of confusion is the difference between Quality Assurance (QA) and auditing. What exactly is the difference between assuring quality and conducting audits?

An audit is “an activity where an independent party investigates and evaluates, typically through sampling, whether quality control and quality assurance processes and systems are functioning appropriately.” The key point is that audits are conducted by an independent department, either periodically or irregularly, examining processes and deliverables through sampling.

The characteristics of auditing are as follows: An important point to note is that both QC and QA are non-audit departments. Audits are conducted on QC departments as well as on quality assurance departments. A common misunderstanding in many companies is the belief that the quality assurance department is the audit department, while all other departments are audited departments. This is incorrect.

A major difference between QC and QA versus auditing is that QA is implemented on an ongoing basis, while audits are retrospective evaluations. When problems are discovered during an audit, it may already be too late to address them effectively.

Some people believe that “if we pass an audit, quality is assured.” Therefore, some say, “We passed the audit, so our responsibility is fulfilled.” This is decidedly not the case.

Another misconception is that some stakeholders believe auditing equals quality assurance. However, this is not accurate. As mentioned earlier, audits involve sampling and do not check everything. Unlike QC or QA, which comprehensively check all items, audits do not cover everything. Therefore, conducting an audit does not equal assured quality.

It is important to note that while auditing is part of quality assurance activities, it is not the entirety of quality assurance.

Comprehensive Comparison of QC, QA, and Audit

The following table summarizes the main differences between QC, QA, and audit:

| Aspect | QC (Quality Control) | QA (Quality Assurance) | Audit |

| Primary Focus | Product/process measurement, evaluation, and adjustment | Systematic establishment and operation of quality assurance systems | Independent verification of system effectiveness |

| Scope | Specific products, processes, or operations | Entire quality management system across all stages | Selected sampling of processes and outcomes |

| Timing | Ongoing, real-time during operations | Ongoing, continuous throughout product lifecycle | Periodic or irregular, retrospective |

| Performer | Personnel directly involved in the work (self-inspection) | Can be performed by department members or dedicated QA personnel | Independent department or external auditors |

| Coverage | Comprehensive check of target items | Systematic coverage of quality-related activities | Sampling-based examination |

| Purpose | Detect and correct deviations, continuous improvement | Ensure systematic quality throughout the organization | Verify compliance and system effectiveness |

| Nature | Operational level activity | Strategic and systematic activity | Independent verification activity |

| Relationship | Part of daily operations | Encompasses QC and extends beyond | Evaluates both QC and QA activities |

Accurately understanding these three concepts and implementing them appropriately is essential for the effective establishment and operation of a quality management system. QC, QA, and auditing each play important roles in ensuring quality, and it is crucial to recognize their differences while ensuring they work together in coordination.

In the pharmaceutical industry and other regulated sectors, these distinctions align with international standards such as ISO 9001 (Quality Management Systems), ISO 13485 (Medical Devices), and regulatory requirements including FDA regulations (21 CFR Part 211 for pharmaceuticals), EU GMP guidelines, and ICH Q10 (Pharmaceutical Quality System). Understanding and properly implementing QC, QA, and auditing in accordance with these standards and regulations is fundamental to maintaining compliance and ensuring product quality and patient safety.

The key takeaway is that quality cannot be achieved through auditing alone. Rather, it requires a comprehensive approach where quality is built into processes through effective QC, systematically assured through robust QA programs, and independently verified through auditing. All three elements must work together as part of an integrated quality management system.

Comment