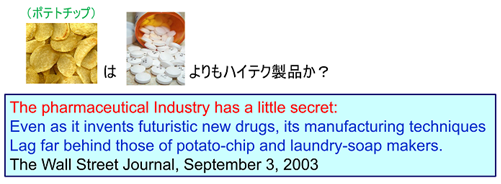

Is the potato chip a more high-tech product than pharmaceuticals?

Pharmaceutical and medical device companies were reluctant to invest in IT and automation systems.

The reason for this is because of regulatory requirements such as Part 11 and CSV.

CSV forces a lot of documentation and testing, which must be presented and explained during regulatory inspections.

CSV implementation requires a lot of time, effort, and cost.

Even so, they may still receive pointers during regulatory inspections. Companies have been frightened of being pointed out by regulators or, in the worst case scenario, issuing a Warning Letter.

These have been the main culprits that have slowed innovation in the pharmaceutical and medical device industries.

In other industries, such as the food and chemical industries, the implementation of IT systems and automation systems have lowered costs and improved quality.

The following article appeared in The Wall Street Journal on September 3, 2003.

The pharmaceutical industry has a little secret:

Even if they develop breakthrough new drugs, their manufacturing technology lags far behind that of makers of potato chips and laundry soap.

Potato chips with a constant hardness can be produced even if the moisture content of the potato changes. What if we were to translate this situation to the manufacture of pharmaceuticals?

From CSV to CSA

Documents for CSV and Part 11 compliance have been prepared only for presentation to inspectors during inspections, without contributing in any way to assuring patient safety or product quality.

In other words, compliance has been a major burden.

Compliance costs spent on CSV and Part 11 compliance have been consumed not for the sake of patients, but for the sake of inspections. Too much work has been done not for fear of putting poor quality products on the market, but for fear that inspections will point them out.

The compliance costs incurred by the companies are passed on to the drug price, resulting in a burden on the patient. This is a complete disaster.

On September 13, 2022, the FDA released draft guidance “Computer Software Assurance for Production and Quality System Software” (“CSA Guidance”).

The CSA Guidance is a fundamental review of CSV, which has been the biggest barrier to the implementation of automated systems by the pharmaceutical and medical device industries.

Instead of documentation for documentation’s sake as in the past, the report introduces recommendations such as the introduction of ad hoc testing without scripts or test logs, and minimal documentation. Appropriate implementation of CSA will give impetus to the electronicization of the pharmaceutical and medical device industries, and will lead to further technological innovation.

Comment