Why Retrospective Validation Is No Longer Acceptable (Revised Edition)

Regulatory Evolution and International Harmonization

On August 30, 2013, the Japanese Ministry of Health, Labour and Welfare (MHLW) issued Notification No. 0830-1 from the Director of the Compliance and Narcotics Division titled “Handling of the Ministerial Ordinance on Standards for Manufacturing Control and Quality Control of Drugs and Quasi-drugs.” This notification amended the GMP Implementation Notice (Notification No. 0330001, dated March 30, 2005), which had been issued in conjunction with the partial revision of the Pharmaceutical Affairs Law. A key aspect of this amendment was the comprehensive revision of validation standards.

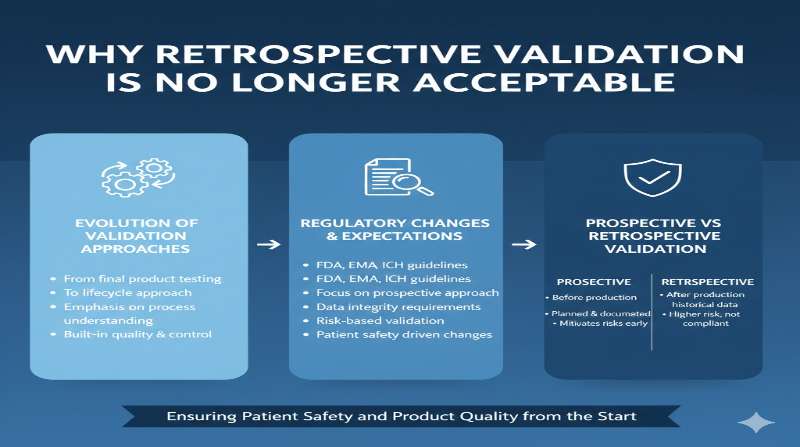

The most significant change in this revision was the elimination of “retrospective validation.” This change was not unique to Japan but aligned with the international trend toward GMP harmonization.

Alignment with International Regulatory Trends

The U.S. Food and Drug Administration (FDA) issued “Process Validation: General Principles and Practices” in January 2011. This new guidance represented a major revision from the 1987 guideline and introduced a lifecycle approach to validation spanning the entire product lifecycle. The new approach did not use traditional terms such as “Prospective,” “Retrospective,” and “Concurrent” validation. Instead, it introduced a three-stage lifecycle approach:

- Stage 1: Process Design

- Stage 2: Process Qualification

- Stage 3: Continued Process Verification

This new approach moved away from the traditional “three-lot validation” concept and emphasized scientifically based continuous verification throughout the product lifecycle, beginning before commercial production starts.

The European Medicines Agency (EMA) also eliminated retrospective validation in the revised PIC/S GMP Annex 15 “Qualification and Validation,” which came into effect on October 1, 2015. The revised version explicitly stated that retrospective process validation is no longer considered an acceptable approach.

This aligned Japan, the United States, and Europe—the major pharmaceutical regulatory authorities—in their position against retrospective validation. This international harmonization reflects the globalization of the pharmaceutical industry and the transition to a more scientific and robust validation approach.

Historical Background of Retrospective Validation

Why did retrospective validation exist in the first place?

When the concept of validation was initially introduced into pharmaceutical manufacturing, many manufacturing facilities had already been operating for extended periods. Some of these facilities had repurposed equipment and structures originally installed for other industries, such as food or chemicals, for pharmaceutical manufacturing. Since these other industries did not perform validation when installing their equipment, retrospective validation was permitted when the facilities were adapted for pharmaceutical use.

Additionally, during the 1980s through early 2000s, when the concept of validation was relatively new, retrospective validation allowed for a phased approach to GMP compliance for existing manufacturing processes. However, now that sufficient time has passed since the establishment of validation concepts in pharmaceutical manufacturing, the prevailing view is that all new or modified processes should be properly validated before commercial production begins.

Currently, repurposing equipment from other industries is essentially no longer acceptable, and all new processes are required to be validated prospectively. This can be seen as a return to the fundamental GMP principle of ensuring patient safety and product quality.

Impact on Computerized System Validation (CSV)

The validation standards mentioned above do not directly address Computerized System Validation (CSV). However, the validation approach for CSV is based on principles common to process validation.

Hardware (H/W) degrades over time and therefore requires periodic re-qualification. This is because physical equipment may experience changes in performance due to wear and deterioration over time.

Software (S/W), on the other hand, does not degrade over time and does not fail in the same way. While the software code itself does not change, it can be affected by changes in the surrounding environment (operating systems, hardware, interfaces, etc.).

Therefore, the concept of “periodic revalidation” is not necessarily required for software. However, this does not mean that software verification is unnecessary. Rather, continuous management based on a lifecycle approach is important.

Key Software Management Considerations

Importance of Change Management

Software typically undergoes more frequent changes than hardware. Therefore, validation at the time of changes is critically important. Changes include:

- Software version upgrades

- Configuration changes

- Interface modifications

- Changes in the operating environment

Periodic Review

EU GMP Annex 11 “Computerised Systems” (2011 version) requires that computerized systems be periodically evaluated to confirm that they remain in a validated state and are compliant with GMP. This is not “revalidation” but rather a “periodic review” to confirm that the system continues to be suitable for its intended use.

It should be noted that a draft revision of Annex 11 was published in 2025, advancing toward a more comprehensive digital governance framework that includes cloud services, artificial intelligence/machine learning systems, and enhanced cybersecurity requirements.

Continued Process Verification

Modern validation approaches emphasize not only initial validation activities but also continuous verification during the commercial production stage. This includes:

- Continuous monitoring of system performance

- Management and trend analysis of deviations

- Ensuring data integrity

- Review of audit trails

Importance of the Lifecycle Approach

Current validation regulations require continuous verification throughout the product and process lifecycle rather than verification at a single point in time. This concept is reflected in the following international guidelines:

- ICH Q8 (Pharmaceutical Development)

- ICH Q9 (Quality Risk Management)

- ICH Q10 (Pharmaceutical Quality System)

- ICH Q11 (Development and Manufacture of Drug Substances)

These guidelines emphasize scientific understanding from the development stage and a risk-based approach, based on Quality by Design (QbD) principles.

Implementation of Risk-Based Approaches

Validation activities should be prioritized based on risk assessment. Organizations are required to focus on Critical Quality Attributes (CQAs) and Critical Process Parameters (CPPs), developing appropriate validation strategies that consider patient risk and impact on product quality.

Summary

The elimination of retrospective validation demonstrates the evolution of quality assurance thinking in pharmaceutical manufacturing from retrospective verification to prospective and continuous verification. The current regulatory environment requires:

- Prospective Approach: All new processes and changes must be properly validated before commercial production begins

- Lifecycle Management: Continuous verification and improvement throughout the product lifecycle

- Scientific Evidence: Data-driven scientific understanding and risk-based decision making

- International Harmonization: Alignment of requirements among major regulatory authorities

These requirements ultimately contribute to the fundamental GMP objective of ensuring patient safety and product quality. It is important for pharmaceutical companies to view these requirements not merely as compliance obligations but as opportunities for continuous quality improvement.

Related Articles

- Why Software Category Classification is Necessary

- The Purpose and Importance of Installation Qualification (IQ) in the Pharmaceutical Industry

- Understanding the True Purpose of Performance Qualification (PQ) in Computerized System Validation

- Purpose and Proper Development of Validation Reports

- Understanding Quality Control (QC) in Pharmaceutical Manufacturing: Beyond Inspection to Process Excellence

Comment