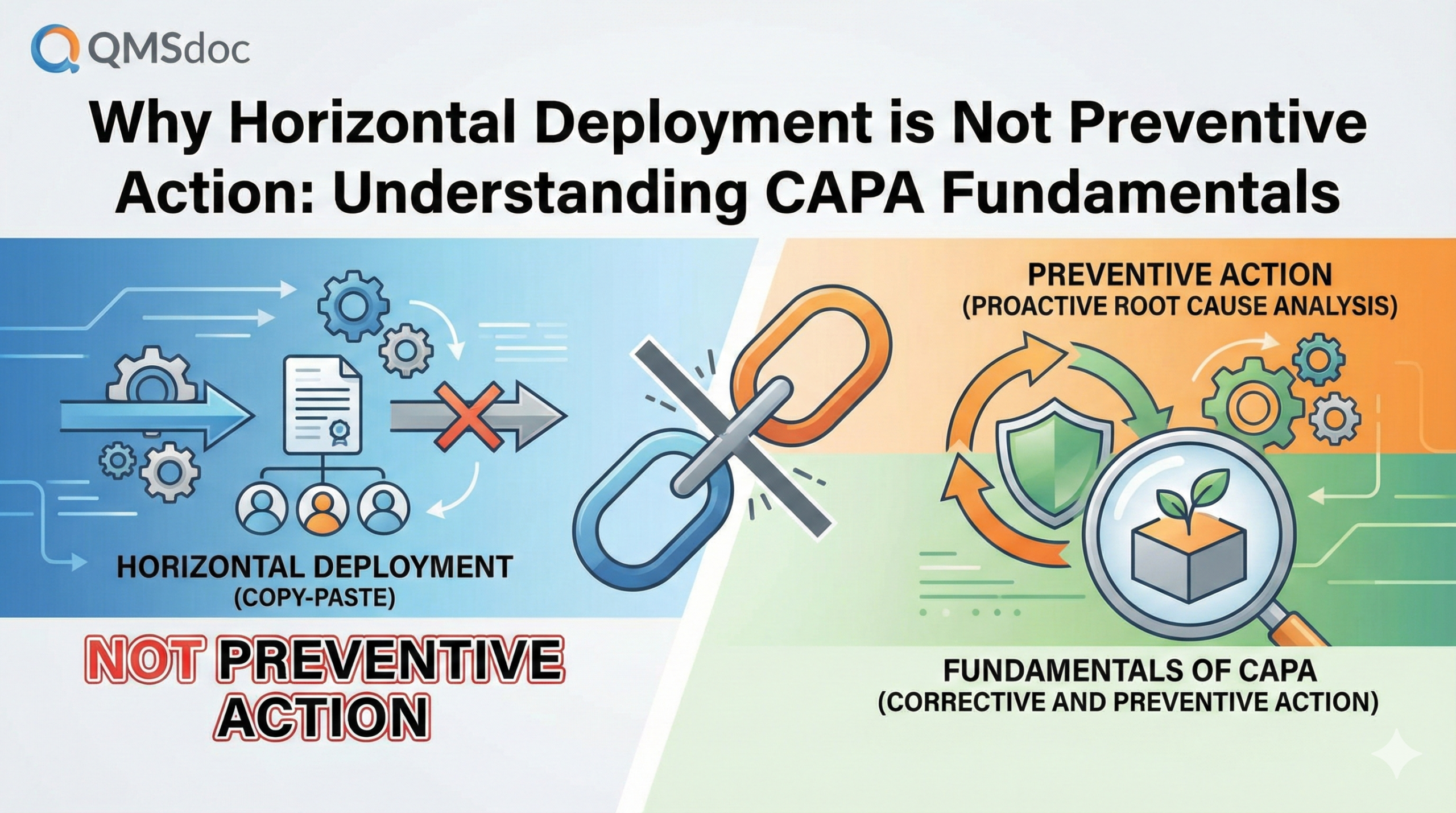

Why Horizontal Deployment is Not Preventive Action: Understanding CAPA Fundamentals

Introduction

When conducting seminars on CAPA (Corrective Action and Preventive Action), I frequently encounter a particular question from participants: “What is the rationale for stating that horizontal deployment is not preventive action?” This question reflects a common area of confusion in quality management systems, particularly as organizations strive to implement effective CAPA processes that comply with international standards.

In my CAPA seminars, I consistently explain that horizontal deployment should be classified as corrective action rather than preventive action. This distinction is not merely semantic but reflects fundamental principles of quality management and risk-based thinking. This article examines why horizontal deployment aligns with corrective action, explores the definitions and concepts underlying this classification, and emphasizes what truly matters in maintaining product quality and patient safety.

The Critical Importance of Horizontal Deployment

Before delving into the classification debate, it is essential to acknowledge the vital role that horizontal deployment plays in quality management systems. When a root cause is identified for a nonconformity in one product or process, that same root cause may exist—often undetected—in other products or processes within the organization. Horizontal deployment, also known as lateral deployment or “yokoten” in Japanese manufacturing terminology, involves systematically applying corrective actions across similar products, processes, or locations to address potentially identical root causes before they manifest as problems.

This practice is extremely important because it:

- Prevents the same failure from occurring in related areas

- Leverages learning from one incident to protect multiple areas

- Demonstrates systematic thinking in quality management

- Reduces the likelihood of repeated customer complaints or safety incidents

- Optimizes resource utilization by addressing multiple potential issues simultaneously

Organizations that effectively implement horizontal deployment demonstrate mature quality management systems and a proactive approach to protecting product quality and patient safety.

Fundamental Definitions: Corrective Action vs. Preventive Action

To understand why horizontal deployment is classified as corrective action, we must first clearly define the core concepts of CAPA.

Corrective Action

Corrective action addresses events that have already occurred (past tense) and aims to prevent their recurrence. According to ISO 9000:2015 (JIS Q 9000:2015), corrective action is defined as “action to eliminate the cause of a nonconformity and to prevent recurrence.” The key characteristic is that corrective action responds to something that has already happened—a detected nonconformity, a customer complaint, an audit finding, or any identified problem.

Preventive Action in Historical Context

Preventive action, as defined in ISO 9000:2015 (JIS Q 9000:2015), is “action to eliminate the cause of a potential nonconformity or other potential undesirable situation.” The critical phrase here is “potential nonconformity”—referring to problems that have not yet occurred. Preventive action addresses risk (future tense) and aims to prevent issues before they manifest.

The definition emphasizes dealing with something that “may occur” rather than something that “has occurred.” True preventive action involves identifying risks through methods such as:

- Risk assessment and risk analysis (FMEA – Failure Mode and Effects Analysis)

- Process capability studies

- Trend analysis of quality data

- Proactive identification of potential failure modes

- Design reviews and design validation activities

The Evolution to Risk-Based Thinking in ISO 9001:2015

It is important to note a significant evolution in the ISO 9001 standard. ISO 9001:2015 replaced the specific clause on preventive action with the broader concept of “risk-based thinking.” This change does not diminish the importance of prevention; rather, it embeds preventive thinking throughout the entire quality management system rather than treating it as a separate, isolated activity.

Risk-based thinking in ISO 9001:2015 requires organizations to:

- Consider risks and opportunities when planning the QMS

- Determine and address risks and opportunities that affect the QMS’s ability to achieve intended results

- Prevent or reduce undesired effects

- Achieve continual improvement

This shift from reactive preventive action to proactive risk-based thinking represents a more comprehensive and integrated approach to prevention. However, other standards—particularly those in regulated industries such as ISO 13485:2016 for medical devices and FDA 21 CFR Part 820—continue to maintain explicit requirements for both corrective and preventive actions as distinct processes.

Why Horizontal Deployment is Corrective Action, Not Preventive Action

The Core Logic

Horizontal deployment applies actions based on a root cause that has already been identified from an event that has already occurred. Consider the following logical sequence:

| Step | Description | Time Frame |

| 1. Problem Occurrence | A nonconformity or failure occurs in Product A or Process X | Past (Already happened) |

| 2. Investigation | Root cause analysis identifies the underlying cause | Present (Investigating past event) |

| 3. Corrective Action | Actions implemented to address the root cause in Product A or Process X | Present (Addressing past event) |

| 4. Horizontal Deployment | The same corrective actions applied to Products B, C, D or Processes Y, Z | Present (Still addressing past event) |

The critical insight is that horizontal deployment addresses the same root cause that was discovered through investigation of a past event. Even though the nonconformity has not yet occurred in Products B, C, or D, the root cause that led to the failure in Product A already exists in these other products or processes. The organization is not preventing a potential future problem; rather, it is addressing an existing condition that has simply not yet manifested as a detected nonconformity.

Distinguishing Risk from Existing Conditions

The ISO definition of preventive action specifically refers to “potential nonconformity” or risk—something that might occur in the future. True risk identification involves proactive analysis to discover conditions or scenarios that could lead to problems, even when no problems have yet occurred anywhere in the organization.

In contrast, horizontal deployment occurs after:

- A problem has already occurred (in at least one location)

- The root cause has been identified through investigation of that actual problem

- Evidence exists that this root cause can lead to nonconformities

This is not risk management; this is managing the spread of a known cause of failure.

Consider this analogy:

- Preventive Action (Risk-based): Before any incidents, conducting a FMEA analysis identifies that inadequate temperature control in a sterilization process could potentially lead to sterility failures. Implementing enhanced temperature monitoring based on this proactive analysis is preventive action.

- Corrective Action with Horizontal Deployment: A sterility failure occurs in Production Line 1, and investigation reveals inadequate temperature control as the root cause. Implementing temperature monitoring in Production Line 1 is corrective action. Subsequently, recognizing that Production Lines 2, 3, and 4 use the same sterilization process, implementing temperature monitoring in these lines is horizontal deployment—still fundamentally corrective action addressing a known cause of failure.

In the second scenario, the organization did not identify a potential risk through proactive analysis. Instead, the organization discovered an actual cause of failure and is now ensuring that the same cause does not produce additional failures elsewhere. The root cause already exists; it simply has not yet been detected or has not yet led to a detected nonconformity in the other locations.

What Horizontal Deployment Does Not Accomplish

When implementing horizontal deployment:

- You have not discovered a new, previously unknown risk

- You have not prevented a potential problem through proactive risk assessment

- You have not conducted forward-looking risk analysis

Rather, you have:

- Responded to an event that already occurred

- Extended the corrective action from one location to other similar locations

- Addressed the same root cause that has already caused a problem

Contemporary Regulatory Perspectives

Medical Device Industry Standards

In the medical device industry, which operates under stringent regulatory oversight, both ISO 13485:2016 and FDA 21 CFR Part 820 maintain distinct requirements for corrective and preventive actions:

ISO 13485:2016:

- Clause 8.5.2 (Corrective Action): Organizations must take action to eliminate the cause of nonconformities to prevent recurrence. This includes reviewing nonconformities (including complaints), determining causes, evaluating the need for action, implementing action, recording results, and reviewing effectiveness.

- Clause 8.5.3 (Preventive Action): Organizations must determine action to eliminate the causes of potential nonconformities. This involves identifying potential nonconformities and their causes, evaluating the need for action, implementing action, and reviewing effectiveness.

FDA 21 CFR Part 820.100: The U.S. Food and Drug Administration requires medical device manufacturers to establish and maintain procedures for CAPA, including:

- Analyzing processes, work operations, concessions, quality audit reports, quality records, service records, complaints, returned product, and other sources of quality data to identify existing product and quality problems

- Investigating the cause of nonconformities relating to product, processes, and the quality system

- Identifying action needed to correct and prevent recurrence of nonconformities

- Verifying or validating the corrective and preventive action to ensure it is effective

Pharmaceutical Industry Standards

ICH Q10 (Pharmaceutical Quality System) emphasizes CAPA as part of the quality management system, requiring:

- A systematic approach to CAPA that includes investigation, root cause determination, and implementation of effective actions

- Integration of CAPA with change management and management review

- Use of trending and analysis to identify potential quality issues

EU GMP Annex 1 (2022) for sterile medicinal products explicitly requires manufacturers to have a system to address deviations and implement corrective and preventive actions, with emphasis on contamination control strategy.

These regulatory frameworks consistently distinguish between corrective action (responding to actual events) and preventive action (addressing potential issues), though the integration of risk management into these processes has become increasingly sophisticated.

Current Industry Best Practices

Integration with Risk Management

Modern quality management systems increasingly integrate horizontal deployment with formal risk management processes:

- Post-CAPA Risk Assessment: After identifying a root cause and implementing corrective action, conduct a formal risk assessment to determine:

- Which other products, processes, or locations share similar characteristics

- The likelihood that the same root cause exists in these areas

- The potential consequences if the root cause manifests in these areas

- The priority for horizontal deployment based on risk ranking

- Documentation and Justification: Document the rationale for horizontal deployment decisions, including:

- The scope of horizontal deployment (what areas are included and excluded)

- Risk-based justification for the scope

- Verification activities to confirm the root cause exists or does not exist in other areas

- Effectiveness checks specific to horizontally deployed actions

- Systematic Review: Establish procedures that require consideration of horizontal deployment for every significant CAPA, rather than treating it as an optional or ad hoc activity.

Enhanced Horizontal Deployment Framework

| Phase | Activities | Documentation |

| Initial CAPA | Problem occurs, investigation conducted, root cause identified, corrective action implemented | CAPA report with root cause analysis |

| Horizontal Deployment Assessment | Evaluate applicability to other products/processes, perform risk assessment, determine deployment scope | Risk assessment matrix, deployment decision record |

| Implementation | Apply corrective actions to additional locations, verify implementation | Implementation verification records |

| Effectiveness Verification | Confirm actions are effective across all deployed locations, monitor for adequate period | Effectiveness check results, trending data |

| Process Improvement | Update FMEA, control plans, procedures, training materials | Updated quality system documents |

The Practical Perspective: Why the Debate Matters Less Than Action

While I maintain that horizontal deployment is technically corrective action rather than preventive action based on the logical framework and definitions outlined above, I must emphasize a crucial point: the debate over classification is far less important than the commitment to action.

What Truly Matters

The paramount concern in any quality management system is not whether an activity is labeled as “corrective” or “preventive” action. What genuinely matters is that organizations:

- Thoroughly investigate nonconformities to identify true root causes rather than addressing symptoms

- Implement effective actions that eliminate the root cause and prevent recurrence

- Consider broader implications by asking “where else could this root cause exist?”

- Take systematic action to address identified issues wherever they may exist

- Verify effectiveness of all actions through appropriate monitoring and measurement

- Maintain proactive risk assessment to identify and address potential problems before they occur

- Ensure patient safety and product quality through all means available

Whether you call horizontal deployment “corrective action,” “preventive action,” or create a distinct category for it, the critical success factor is that you do it systematically and effectively.

The Real Value Proposition

Organizations should focus their energy on:

- Asking the right questions: “Could this root cause exist elsewhere?” “What other products or processes might be affected?”

- Taking comprehensive action: Not limiting corrective actions to only the location where a problem was detected

- Implementing robust systems: Establishing procedures that require consideration of horizontal deployment

- Building quality culture: Creating an environment where sharing problems and solutions across the organization is expected and valued

- Protecting stakeholders: Ensuring that patients, customers, and end-users receive safe, effective, and high-quality products

Avoiding Counterproductive Debates

Auditors, quality managers, and regulatory inspectors should avoid becoming mired in semantic debates about whether horizontal deployment is corrective or preventive action. Instead, evaluations should focus on:

- Is horizontal deployment being considered and implemented where appropriate?

- Are the deployed actions effective?

- Is the organization learning from problems and applying lessons broadly?

- Are quality and safety being protected?

The terminology is secondary to the substance of the quality management system’s performance.

Conclusion: Clarity in Concept, Focus on Impact

To summarize the key principles addressed in this article:

Classification Logic: Horizontal deployment is fundamentally corrective action because it addresses a root cause identified from a past event, even when applying that action to locations where the nonconformity has not yet manifested. It responds to an existing condition rather than preventing a potential future risk that has been proactively identified.

Definitional Basis:

- Corrective Action: Eliminates the cause of detected nonconformities to prevent recurrence (past tense, actual events)

- Preventive Action: Eliminates the cause of potential nonconformities to prevent occurrence (future tense, risks)

- Risk-Based Thinking (ISO 9001:2015): Considers risks and opportunities throughout the QMS to prevent undesired effects (proactive, forward-looking)

- Horizontal Deployment: Applies corrective actions to similar products/processes where the same root cause may exist (responding to known causes identified from past events)

Regulatory Evolution: While ISO 9001:2015 has integrated preventive action into broader risk-based thinking, industry-specific standards (ISO 13485, FDA 21 CFR Part 820) maintain distinct CAPA requirements. All frameworks emphasize the importance of systematic approaches to both preventing problems and correcting them when they occur.

Practical Imperative: Regardless of how horizontal deployment is classified, what matters most is that organizations:

- Implement robust CAPA processes

- Consider horizontal deployment systematically

- Take effective action to prevent recurrence and protect quality

- Maintain focus on patient safety and product quality

- Foster a culture of continuous improvement and shared learning

Final Thought: The sophistication of a quality management system is not demonstrated by winning debates about terminology but by consistently delivering safe, effective, high-quality products while continuously improving processes and preventing problems—both those that have occurred and those that might occur. Horizontal deployment, corrective action, preventive action, and risk-based thinking are all essential tools in achieving this goal.

Organizations that combine rigorous corrective action (including systematic horizontal deployment) with proactive risk-based thinking create the most robust protection for product quality and patient safety. Rather than debating classifications, quality professionals should ensure that both reactive correction and proactive prevention receive appropriate attention and resources in their quality management systems.

About CAPA in Modern Quality Management

Corrective Action and Preventive Action (CAPA) remain central to quality management across industries, particularly in regulated sectors such as pharmaceuticals, medical devices, and biotechnology. Effective CAPA systems integrate with broader quality management processes including:

- Complaint handling and adverse event reporting

- Internal and external audit findings

- Nonconformance management

- Change control and management of change

- Risk management and FMEA

- Process validation and verification

- Post-market surveillance and vigilance

- Management review and continual improvement

As quality management continues to evolve toward more integrated, risk-based approaches, the principles underlying CAPA—thorough investigation, effective action, and systematic prevention—remain as relevant as ever. Organizations that master these fundamentals, regardless of terminology debates, position themselves for sustained quality excellence and regulatory compliance.

Comment