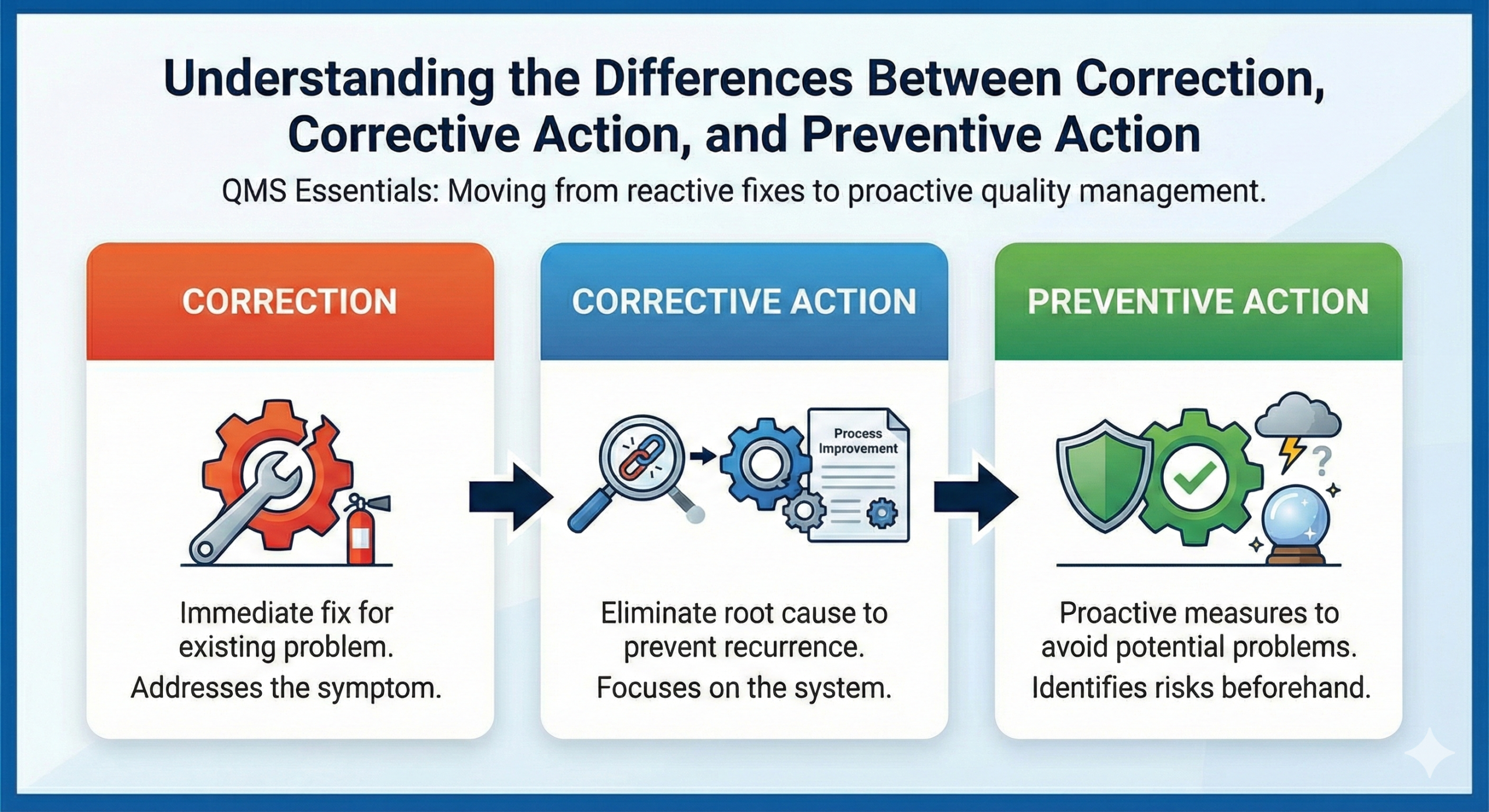

Understanding the Differences Between Correction, Corrective Action, and Preventive Action

In the world of quality management, three concepts are essential when responding to problems: “correction,” “corrective action,” and “preventive action.” While these may seem similar at first glance, there are clear differences in their purpose and scope of application. This article explains these three concepts in a way that is easy for beginners to understand.

What is Correction?

Correction refers to the act of eliminating a detected nonconformity (problem or defect) itself. In other words, it is an immediate response to resolve the problem at hand. For example, if there is a scratch on a product, the scratch is polished away. If there is a typographical error in a document, the error is corrected. If a machine has stopped, it is restarted. Correction deals with the problem itself and does not aim to investigate the root cause of the problem or prevent similar problems from recurring. It is a concept similar to “symptomatic treatment.”

Important consideration: If response is concluded with correction alone, the same problem is likely to recur because the fundamental cause has not been resolved. For example, simply polishing away a scratch on a product will not improve the manufacturing line issues, so the same scratch will likely occur on the next product. Therefore, it is crucial in quality management not only to perform correction but also to proceed to corrective action. Additionally, implementing preventive measures from a risk management perspective is essential. Correction should be recognized as an emergency measure for a problem, not a permanent solution.

What is Corrective Action?

Corrective action is an activity to identify the cause of a detected nonconformity and eliminate that cause so that “the same thing does not happen in the same place.” In essence, corrective action is about reliably preventing the recurrence of past problems in specific locations or situations. For example, if scratches frequently occur on products, the problems in the manufacturing line are investigated and equipment improvements are made. If there are many typographical errors in documents, the checking system is reviewed and double-checking is introduced. If a machine frequently stops, the cause of the stoppage is analyzed, and parts are replaced or settings are changed. Corrective action focuses on pursuing “why the problem occurred” as the root cause and eliminating that cause. This prevents the same problem from recurring under the same conditions. The effectiveness of corrective action is evaluated by whether appropriate measures have been taken against the identified cause and whether “the same nonconformity no longer occurs in the same place.”

What is Preventive Action?

Preventive action is an activity to anticipate potential nonconformities that have not yet occurred and prevent their occurrence. While corrective action responds to past problems, preventive action is a proactive response to problems that may occur in the future. An important point is that this “potential nonconformity” is synonymous with “risk.” In other words, preventive action can be understood as a form of risk management. For example, if a problem that occurred with a similar product is predicted to also occur with our own product, design changes are made in advance. If quality problems are predicted due to seasonal variations, manufacturing conditions are adjusted in advance. If an increase in system load is predicted, capacity is increased in advance. Preventive action is an activity that predicts “what could become a problem” and takes measures before the problem becomes apparent, thereby preventing the occurrence of the problem itself.

Definitions in ISO 9000

In ISO 9000 (Quality management systems — Fundamentals and vocabulary), these terms are clearly defined as follows.

Definition of Correction

According to definition 3.12.3 in ISO 9000:2015: “action to eliminate a detected nonconformity.” The note states: “A correction can be made, for example, in conjunction with a corrective action or can include rework or regrade.”

Definition of Corrective Action

According to definition 3.12.2 in ISO 9000:2015: “action to eliminate the cause of a nonconformity and to prevent recurrence.” The following three points are indicated in the notes:

Note 1: There can be more than one cause of a nonconformity.

Note 2: Corrective action is taken to prevent recurrence.

Note 3: There is a distinction between corrective action and preventive action.

Definition of Preventive Action

According to definition 3.12.1 in ISO 9000:2015: “action to eliminate the cause of a potential nonconformity or other potential undesirable situation.” The following three points are indicated in the notes:

Note 1: There can be more than one cause for a potential nonconformity.

Note 2: Preventive action is taken to prevent occurrence.

Note 3: Preventive action is taken to deal with a potential situation, whereas corrective action is taken to deal with an actual situation.

The Relationship Among the Three Concepts

The relationship among these three concepts can be organized as follows: Correction eliminates the nonconformity in front of us (problem response). Corrective action removes the cause of the occurred nonconformity and prevents recurrence (recurrence prevention). Preventive action anticipates potential nonconformities and prevents their occurrence (proactive prevention). From a time axis perspective, correction responds to “present” problems, corrective action prevents recurrence of “past” problems, and preventive action prevents the occurrence of “future” potential problems.

The following table summarizes the key differences:

| Concept | Time Frame | Purpose | Focus |

| Correction | Present | Eliminate the nonconformity itself | The problem itself |

| Corrective Action | Past | Remove the cause to prevent recurrence | The root cause |

| Preventive Action | Future | Prevent occurrence of potential problems | Potential risks |

Relationship with ISO Standards

These concepts also occupy an important position in ISO 9001, the international standard for quality management systems. A noteworthy point is that in ISO 9001:2015, corrective action remains as a requirement, but the item “preventive action” itself has been removed. This is because the preventive concept has been developmentally integrated into the concept of “risks and opportunities” and distributed throughout various clauses of the standard.

In other words, in ISO 9001:2015, rather than having preventive action as a separate requirement, risk-based thinking is incorporated throughout the entire standard. Organizations are now required to consider risks and opportunities from the planning stage of the quality management system and to respond based on that consideration. As a result, the concept of preventive action has come to be applied more comprehensively and integrally.

This change means that the quality management system has become more strategic and business-oriented, directly contributing to the achievement of the organization’s intended objectives.

Concrete Example: The Case of a Fatal Drunk Driving Accident

When quality management concepts are also applied to social problems, understanding deepens. Here, we will use the example of a fatal drunk driving accident to concretely explain the differences among emergency treatment, correction, corrective action, and preventive action.

Emergency Treatment

Emergency treatment refers to temporary measures to respond immediately to an emergency situation that has occurred and prevent the damage from expanding. Examples include life-saving measures such as stopping bleeding from the injured or performing cardiopulmonary resuscitation, contacting ambulances and police, and alerting the surroundings to prevent secondary accidents. These are immediate responses to emergency situations, but they do not eliminate the cause of the accident itself.

Correction

Correction refers to resolving the problem itself. Examples include moving the accident vehicle and people to the shoulder or other safe locations, restraining the drunk driver at the scene to eliminate the dangerous situation, and repairing damaged road signs and guardrails. These actions restore the abnormal state caused by the accident to a normal state, but they do not reduce the possibility of similar accidents recurring.

Corrective Action

Corrective action refers to identifying the cause of a problem and taking measures so that the same problem does not recur in the same place or situation. Examples include revoking the driver’s license of the relevant driver so that the same driver cannot drive drunk again, conducting education on the dangers of drunk driving for the driver who caused the accident, installing curve mirrors or improving road design if there are problems with the road design at the accident site, and strengthening drunk driving checkpoints and stricter enforcement. These are measures to prevent recurrence in specific locations or situations, addressing the causes of “why the accident occurred.”

Preventive Action

Preventive action refers to activities to anticipate potential risks that have not yet occurred and prevent the problem itself from occurring. Examples include strengthening laws, such as establishing the crime of causing death or injury by dangerous driving, mandating ignition interlock systems using alcohol detectors for vehicles, conducting awareness-raising activities throughout society about the dangers of drunk driving, and promoting designated driver services and expanding nighttime operation of public transportation. These are preventive measures to prevent the occurrence of all potential drunk driving accidents. According to the thinking of ISO 9001:2015, such preventive actions should be systematically addressed as risk management.

Differences in Time Axis and Scope of Application

What is clearly visible from this example is the difference in time axis and scope of application. Emergency treatment and correction are immediate responses to the current emergency or abnormal situation (responses immediately after the accident). Corrective action involves recurrence prevention measures against specific causes (measures for specific drivers or specific locations). Preventive action involves proactive prevention measures against potential risks (responses to drunk driving risks throughout society). For effective risk management, responses at all these levels are necessary, and it is important to understand the differences among each concept.

Application in Practice

In practice, it is important to use these three concepts in a balanced manner. First, respond to the immediate problem with “correction” (short-term response). Next, analyze the cause of the problem and implement “corrective action” (medium-term response). Furthermore, anticipate the possibility that similar problems may occur in the future and consider “risk management (preventive action approach)” (long-term response). This three-stage approach enables a comprehensive response to problems.

Summary

Correction: An immediate response to eliminate the nonconformity in front of us (however, with this alone, there is a high possibility of recurrence).

Corrective Action: A response to remove the root cause of the nonconformity so that the same problem does not recur in the same place.

Preventive Action: A response to anticipate potential nonconformities (risks) and prevent their occurrence (in current ISO standards, integrated into the entire standard as risk-based thinking).

Understanding these three concepts and using them appropriately becomes the foundation for effective quality management and continuous improvement activities. When problems occur, rather than ending with mere correction, proceeding to corrective action and further considering a preventive approach from a risk management perspective will steadily mature the organization’s quality culture.

Comment